As the trend of sustainability efforts rises across industries, recycling has become a crucial part of protecting the ecosystem, and it hopes to cut down the amount of waste and conserve resources. PET (Polyethylene Terephthalate) is one material that has reopened its path to recycling, from bottles we use for beverages and cleaning products, several consumer goods, etc. The bottles can then be recycled into valuable fibers that can become clothing, upholstery or insulation materials.

At Saheb Fibre focuses primarily on recycling used PET bottles into Recycled Polyester Staple Fiber (RPSF), which is a great product as it helps implement sustainable textile and other industry practices. But, how does that work? So let’s take a look at the journey of a PET bottle to become RPSF.

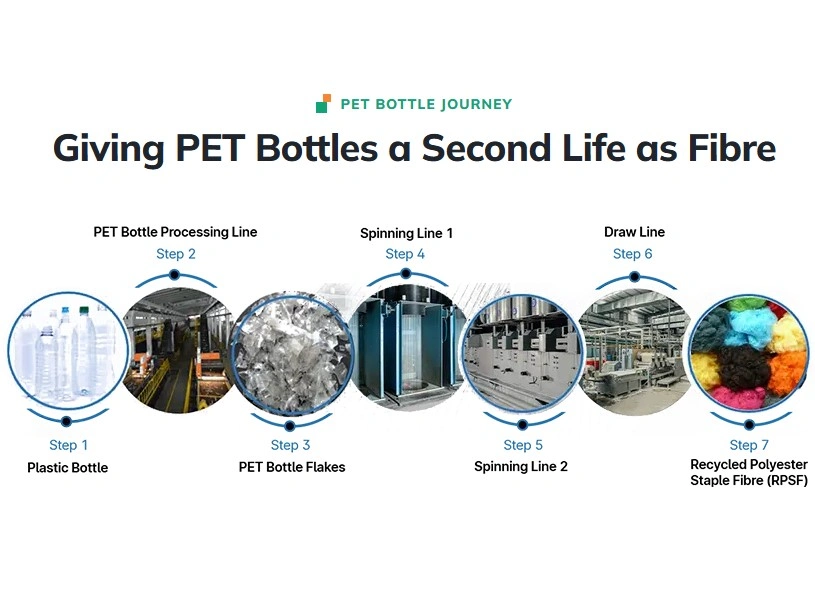

The Journey of PET Bottles: From Waste to RPSF

1. Collection and Sorting of PET Bottles

The recycling process begins with collecting PET bottles. The bottles that we are using were usually obtained from recycling bins, collection centers or by utilising waste disposal services directly. The bottles are then sorted to remove any contaminants like bottle caps and labels and other types of plastic. This sorting process helps prevent impurities contaminating the final product when pure PET plastic is sorted into the recycling stream.

2. Cleaning and Removing Labels

After the PET bottles are sorted, they undergo a rigorous cleaning process. This step requires washing the bottles to remove any remnant liquids, labels and dirt. Bottles are completely sanitized with hot water and detergents. It is crucial that any residue can interfere with the quality of recycled material.

3. Shredding the Bottles

The next step is cleaning the PET bottles and shredding them into small pieces (which are often called flakes). These small PET flakes are easier to process and melt down. The amount and size of the flakes depends on what the recycling facility needs but are cut up into small uniform pieces in order to be consistent in the next few steps of processing.

4. Washing and Further Purification

After shredding, the PET flakes are washed to remove any residual contaminants, such as adhesives from labels, dirt or oil from the bottle contents in a further process called cleaning. It ensures that the material is pure enough for fiber production.

5. Extrusion and Polymerization

After purification, PET flakes are melted and extruded to form polyester chips. The fibers themselves are made from these chips. Some of the chips are polymerized further to boost their properties, such as strength and durability. They also help achieve the desired quality and consistency of the fibers.

6. Spinning and Fiber Formation

The RPSF is then melting again and spinning them into fine threads. The final product for which the fibers will be used determines her length of produced fiber. These fibers can be used in the making of fabrics, insulation materials or as raw material in the manufacturing of new products such as furniture and parts of automotive.

7. Quality Control and Testing

At Saheb Fibre, we ensure that the RPSF produced meets the highest standards of quality. We conduct various tests for their durability, strength, and uniformity. This guarantees that the final products will not only be sustainable, but will also satisfy the needs of industries such as textiles, automotive or construction.

8. Packaging and Distribution

After that, the RPSF is packaged and delivered to the customers. We at Saheb Fibre always choose sustainable packaging options to minimize the environmental blow. Manufacturers then use our RPSF to create a variety of recycled products including clothing to insulation material.

Why is RPSF Important?

Recycled Polyester Staple Fiber (RPSF) is the game changer in the sustainability, textile industry and other manufacturing sectors. As an eco-friendly alternative to virgin polyester, RPSF offers several benefits:

-

It is a recycling of PET bottles and other plastic materials to reduce plastic waste.

-

Helps reduce a carbon footprint from relying on petroleum with virgin polyester.

-

It provides help in waste management to prevent plastics from getting into landfills and oceans.

-

It also requires less energy and resources than virgin polyester production.

Conclusion

The recycling of PET bottles into RPSF is an excellent example of how waste can become valuable material. In this way, industries can contribute to minimizing environmental impact by adopting recycling and sustainability.

Saheb Fibre takes pride in its commitment to provide high-quality, recycled fibers in support of a sustainable future and with innovative solutions for our clients all over the world.