As sustainability becomes a priority across industries, food packaging materials are undergoing a major transformation. Brands are increasingly shifting toward sustainable packaging, but safety remains non-negotiable especially when it comes to plastic food packaging. One of the most common questions asked today is: Is rPET packaging as safe as virgin PET for food-grade applications?

This question is particularly relevant as governments, consumers, and sustainable packaging companies push for environmentally responsible alternatives. In this article, we explore the science, safety standards, regulations, advantages, and limitations of recycled PET packaging, and compare it directly with virgin PET to help businesses make informed decisions.

What Is PET and Why Is It Widely Used in Food Packaging?

PET (Polyethylene Terephthalate) is one of the most commonly used plastic food packaging materials worldwide. Its unique combination of safety, performance, and versatility makes it ideal for food contact applications.

Key reasons PET dominates food packaging materials:

-

High strength and durability

-

Excellent transparency for product visibility

-

Strong barrier against moisture and gases

-

Lightweight yet impact-resistant

-

Chemically stable and food-safe

PET is extensively used in:

-

Bottled water and beverages

-

Edible oil containers

-

Ready-to-eat food trays

-

Dairy and condiment packaging

-

PET food packaging for dry and liquid products

Because of these properties, both virgin PET and rPET have become essential components of modern plastic packaging systems.

What Is Recycled PET (rPET)?

Recycled PET, often referred to as rPET, is produced by recycling post-consumer PET waste such as used bottles and food containers. Through advanced processing, this waste is transformed into new recycled PET packaging suitable for multiple applications.

Types of PET recycling:

-

Mechanical recycling: Cleaning, shredding, and remelting PET

-

Chemical recycling: Breaking PET down to molecular level and rebuilding it

For food-grade rPET packaging, additional purification steps known as “super-clean” processes are used to remove contaminants and ensure safety.

Modern recycling technologies have significantly improved the reliability of recycled PET, making it a key component of eco friendly food packaging solutions.

How rPET Packaging Is Made: From Waste to Food-Grade Material

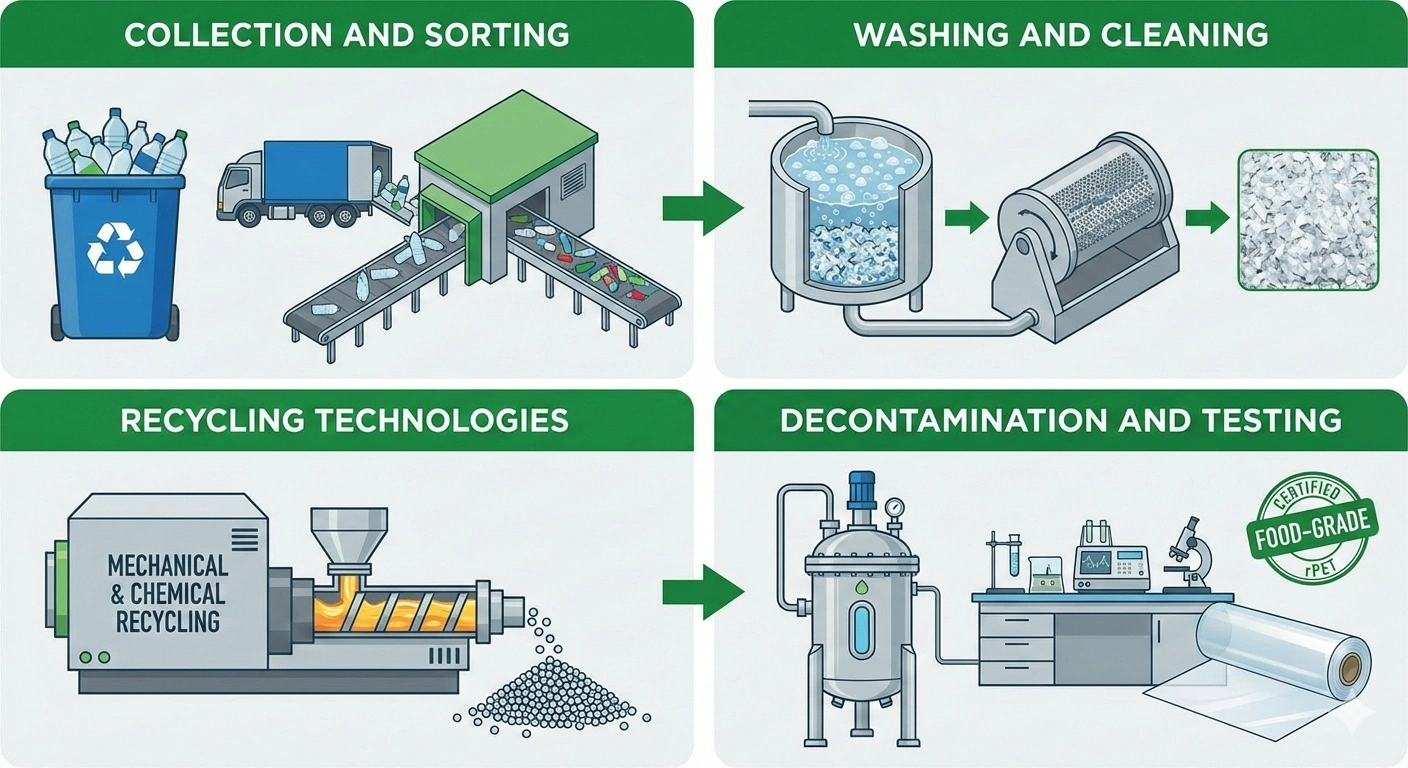

Collection and Sorting

The rPET journey begins with the collection of used PET bottles and containers. These are sorted by type, color, and quality to remove non-PET plastics and contaminants.

Washing and Cleaning

The sorted PET undergoes intensive washing to eliminate food residues, adhesives, labels, and inks. This step is critical for ensuring the final recycled PET packaging meets food safety standards.

Recycling Technologies

There are two main recycling methods:

-

Mechanical Recycling: PET is shredded, melted, and reformed.

-

Chemical Recycling: PET is broken down into monomers and re-polymerized, resulting in extremely high purity.

Chemical recycling is increasingly preferred for eco friendly food packaging, as it produces rPET with properties nearly identical to virgin PET.

Decontamination and Testing

Advanced decontamination processes remove potential chemical residues. Regulatory-approved challenge tests confirm that contaminants are reduced to safe levels.

Once complete, the material is pelletized and ready for use in plastic packaging for food applications.

Food-Grade Safety Standards for PET Packaging

Not all PET materials are automatically safe for food contact. To qualify as food-grade, both virgin PET and rPET must meet strict regulatory requirements.

Major regulatory authorities include:

-

FDA (United States)

-

EFSA (European Union)

-

FSSAI (India)

Food-grade requirements focus on:

-

Chemical migration limits

-

Absence of harmful contaminants

-

Odor and taste neutrality

-

Controlled recycling inputs (for rPET)

-

Traceability and batch testing

Only recycled PET packaging produced through approved processes can legally be used for plastic food packaging applications.

Is Recycled PET Safe for Food Contact?

This is the most critical question in the recycled PET vs virgin PET debate.

The answer is yes recycled PET can be as safe as virgin PET, provided it is produced using approved, food-grade recycling technologies.

Why food-grade rPET is considered safe:

-

Advanced decontamination removes chemical residues

-

High-temperature processing destroys contaminants

-

Strict input control ensures only food-contact PET is recycled

-

Regulatory bodies approve specific recycling processes

-

Migration tests confirm compliance with safety limits

Food-grade rPET packaging is already widely used in:

-

Bottled water

-

Soft drinks

-

Dairy containers

-

Ready-meal trays

The key difference is not the material itself, but how recycled PET is processed and certified.

Virgin PET vs Recycled PET: Safety Comparison

| Factor | Virgin PET | Recycled PET |

|---|---|---|

| Purity | Naturally high | High after approved decontamination |

| Contamination risk | Very low | Controlled and regulated |

| Chemical migration | Minimal | Minimal when food-grade |

| Taste & odor | Neutral | Neutral with proper processing |

| Regulatory approval | Universal | Process-specific approvals |

From a food-safety standpoint, recycled PET vs virgin PET shows minimal differences when rPET is properly certified.

Advantages of rPET Packaging in Food Applications

Environmental Benefits

-

Reduces plastic waste in landfills

-

Lowers carbon footprint

-

Conserves fossil fuels

-

Supports circular economy models

These benefits make rPET a cornerstone of sustainable packaging materials.

Economic and Market Advantages

-

Reduces dependency on volatile raw material prices

-

Aligns with global sustainability mandates

-

Enhances brand reputation

Many sustainable packaging companies now prioritize rPET to meet environmental commitments.

Consumer Trust and Demand

Consumers increasingly prefer brands using eco friendly food packaging, especially when sustainability does not compromise safety.

Challenges and Limitations of Recycled PET Packaging

Feedstock Quality Issues

The quality of rPET depends heavily on proper waste collection and sorting. Contamination at the source can affect final material quality.

Processing Costs

Advanced recycling and decontamination technologies can increase production costs compared to virgin PET especially in regions with limited infrastructure.

Regulatory Complexity

Approval processes vary by country, making global compliance more challenging for manufacturers using recycled PET packaging.

Despite these challenges, technological advancements continue to improve rPET reliability and scalability.

Environmental Impact: Safety vs Sustainability

One of the strongest arguments for rPET packaging is sustainability.

Environmental benefits of recycled PET:

-

Reduces plastic waste

-

Lowers carbon footprint

-

Supports circular economy

-

Conserves fossil fuel resources

-

Aligns with sustainability regulations

Compared to virgin PET, recycled PET packaging can reduce greenhouse gas emissions by up to 50–70%, making it a cornerstone of sustainable packaging materials strategies adopted by leading sustainable packaging companies.

Real-World Use Cases of Food-Grade rPET

Many global brands already rely on recycled PET packaging for food contact.

Common applications include:

-

Bottled water and beverages

-

Yogurt and dairy containers

-

Edible oil bottles

-

Ready-to-eat meal trays

-

PET food packaging for dry foods

These real-world examples prove that rPET is not experimental it is already mainstream.

When Should You Choose Virgin PET vs Recycled PET?

Choose virgin PET when:

-

Ultra-high clarity is essential

-

Regulatory environments are restrictive

-

Premium or sensitive food products are involved

Choose recycled PET when:

-

Sustainability goals are a priority

-

Brand positioning focuses on eco responsibility

-

Regulations permit food-grade rPET use

-

Circular economy adoption is desired

Both materials have their place in modern food packaging materials strategies.

Future of Food-Grade PET Packaging

The future of plastic food packaging is rapidly evolving.

Key trends include:

-

Higher rPET content mandates

-

Advances in chemical recycling

-

Improved transparency and consistency

-

Closed-loop recycling systems

-

Stronger collaboration with sustainable packaging companies

As technology advances, the gap between virgin PET and recycled PET will continue to narrow.

Why Saheb Fibre Is a Trusted Partner for Food-Grade rPET Packaging

Saheb Fibre delivers reliable rPET packaging solutions designed to meet strict food-grade safety and quality standards. With a strong focus on material purity, controlled processing, and regulatory compliance, the company ensures that its recycled PET packaging supports safe food contact while maintaining the performance expected from modern plastic food packaging.

By combining sustainability with consistency, Saheb Fibre helps brands transition toward eco friendly food packaging without compromising safety or reliability. Its commitment to responsible sourcing and advanced manufacturing positions Saheb Fibre among dependable sustainable packaging companies, offering sustainable packaging materials aligned with evolving environmental and regulatory expectations.

Conclusion: Is Recycled PET as Safe as Virgin PET?

The debate around recycled PET vs virgin PET is no longer about safety it’s about implementation and responsibility.

When produced through approved processes, rPET packaging is just as safe for food contact as virgin PET. Regulatory authorities worldwide support its use, and real-world adoption continues to grow.

For brands seeking sustainable packaging, recycled PET offers a proven balance of safety, performance, and environmental responsibility. The future of food packaging lies not in choosing between safety and sustainability but in achieving both.

FAQs – People Also Ask

1. Is recycled PET approved for food packaging?

Yes, food-grade rPET approved by regulatory authorities is safe for food contact.

2. Is rPET safe for bottled water?

Yes, many bottled water brands use certified rPET packaging.

3. Can recycled PET leach chemicals into food?

No, when processed correctly, rPET meets strict migration limits.

4. Is recycled PET better than virgin PET?

From a sustainability perspective, yes while maintaining food safety.

5. What is the future of plastic food packaging?

The industry is shifting toward higher rPET usage and sustainable packaging materials.