Recycled PET fiber is becoming a preferred material in modern textile yarns due to its sustainability and performance benefits. It is made by recycling used plastic bottles and converting them into high-quality polyester fibers. This process helps reduce plastic waste while meeting the growing demand for eco-friendly textiles. Today, textile manufacturers are increasingly using recycled polyester material to create durable, versatile, and cost-effective yarns. Understanding how it works and where it is used can help businesses make informed, sustainable choices.

What Is Recycled PET Fiber?

rPET fiber is a type of polyester fiber produced from post-consumer PET bottles. Instead of sending plastic waste to landfills, these bottles are reused to create textile-grade fibers suitable for various yarn applications.

Understanding rPET Fiber Manufacturing Process

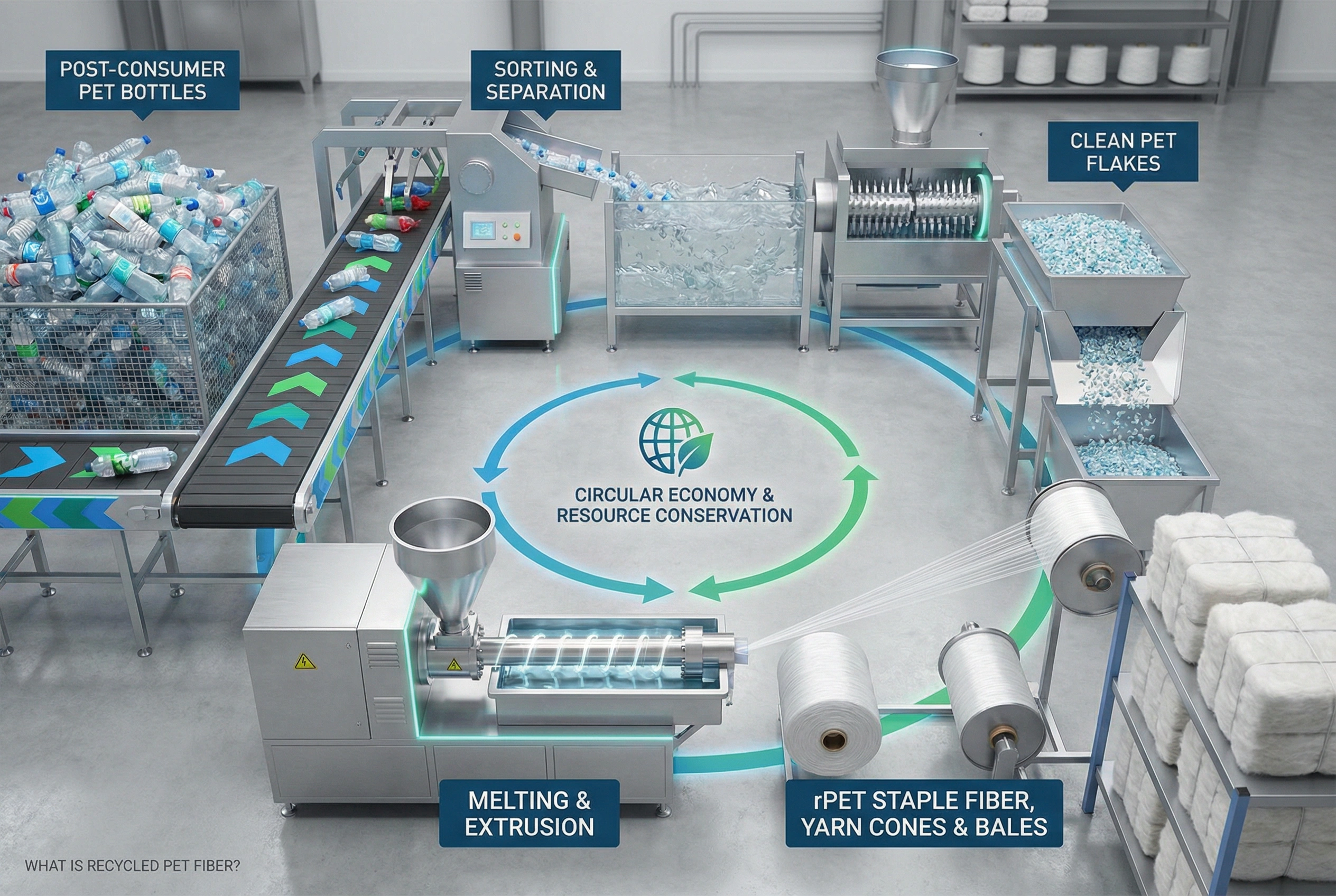

This process enables pet bottle to polyester fibre conversion, where post-consumer plastic bottles are recycled and transformed into high-quality polyester fibers suitable for textile yarn manufacturing.

The process of pet bottle recycling to fiber involves several controlled steps to ensure quality and consistency:

-

Collection of used PET bottles

-

Sorting and removal of contaminants

-

Washing and shredding into flakes

-

Melting and extrusion into fibers

-

Cutting or spinning fibers for textile use

This closed-loop system transforms waste into a valuable raw material while conserving natural resources.

Difference Between Virgin Polyester and Recycled PET Fiber

Virgin polyester is derived from petroleum, while recycled polyester fibers use existing plastic waste. Although both offer similar strength and durability, recycled fiber has a significantly lower environmental impact. It reduces reliance on fossil fuels and minimizes plastic pollution without compromising textile performance.

Why rPET-Based Fibers Are Used in Textile Yarns

Textile yarns made from recycled polyester fibers offer a balance of sustainability, strength, and versatility. This makes them suitable for both everyday and technical applications.

Key Properties of rPET Polyester Fibers

Some important characteristics include:

-

High tensile strength and durability

-

Lightweight structure

-

Resistance to moisture and chemicals

-

Excellent dimensional stability

-

Good thermal performance

These properties allow yarns to maintain shape and quality even after repeated use.

Types of Textile Yarns Made from rPET Fiber

rPET fiber can be processed into different yarn forms depending on end use:

-

Spun yarns for apparel and home textiles

-

Filament yarns for smooth and uniform fabrics

-

Blended yarns combined with cotton or other fibers

Key Benefits of Recycled PET Fiber for Textile Yarns

Environmental Benefits

Using plastic bottle to fiber solutions supports global sustainability goals:

-

Reduces plastic waste in landfills and oceans

-

Lowers greenhouse gas emissions

-

Consumes less energy than virgin polyester production

-

Supports circular economy practices

Performance & Quality Benefits

Despite being recycled, the fiber performs well in demanding textile applications:

-

Comparable strength to conventional polyester

-

Consistent color and dyeability

-

Long product lifespan

-

Suitable for repeated washing

Economic & Business Benefits

From a commercial perspective, rPET-based polyester fibers used in textile yarns offer:

-

Cost efficiency at large production volumes

-

Compliance with environmental regulations

-

Increased acceptance by eco-conscious consumers

-

Improved brand sustainability credentials

Applications of Recycled PET Fiber in Textile Yarns

Apparel & Fashion Industry

Many clothing brands now use plastic bottles to polyester yarn to create:

-

Sportswear and activewear

-

Casual clothing

-

Outerwear and performance garments

The fiber’s moisture resistance and durability make it ideal for daily wear.

Home Textiles

In home furnishing, recycled polyester yarns are widely used for:

-

Carpets and rugs

-

Curtains and upholstery

-

Bed linens and cushions

These products benefit from strength, easy maintenance, and long life.

Industrial & Technical Textiles

Recycled polyester fibers also play a role in industrial sectors such as:

-

Automotive interiors

-

Non-woven fabrics

-

Packaging materials

-

Geotextiles and insulation

Recycled PET Fiber vs Other Sustainable Fibers

|

Feature |

Recycled PET Fiber |

Organic Cotton |

Bamboo Fiber |

|

Raw Material Source |

Plastic bottles |

Natural crop |

Bamboo pulp |

|

Water Consumption |

Low |

High |

Moderate |

|

Durability |

High |

Moderate |

Moderate |

|

Recycling Potential |

High |

Limited |

Limited |

|

Industrial Use |

Wide |

Limited |

Limited |

Compared to natural alternatives, rPET-based polyester fibers offer superior durability and broader industrial usability while reducing plastic waste.

Quality Standards & Certifications for Recycled PET Fiber

Global Recycled Standard (GRS)

GRS certification ensures that recycled content is verified and processed responsibly throughout the supply chain.

OEKO-TEX & Other Certifications

These certifications confirm that fibers are safe for human use and free from harmful substances.

Importance of Traceability and Compliance

Transparent sourcing builds trust with buyers and ensures compliance with international textile standards.

How to Choose the Right Recycled PET Fiber for Textile Yarns

What Factors Should Textile Manufacturers Consider?

Key selection factors include:

-

Fiber length and denier

-

Yarn application requirements

-

Consistency and color stability

-

Reliable supply capacity

Why Fiber Quality Matters in Yarn Production

High-quality fiber ensures smooth spinning, reduced wastage, and better fabric performance.

Role of Sustainable Manufacturers in the rPET Supply Chain

Sustainable producers play a critical role in converting waste into value-added fibers. Ethical manufacturing practices, modern recycling technology, and strict quality control help ensure reliable output and environmental responsibility across the supply chain.

Role of Saheb Fibre in Recycled PET Fiber for Textile Yarns

Saheb Fibre is a trusted recycled polyester fibre manufacturer supplying RPSF and rPET flakes for textile and industrial applications. The company focuses on converting PET waste into high-quality fibers that meet modern textile performance requirements. By supporting sustainable manufacturing practices, Saheb Fibre enables textile producers to adopt eco-friendly materials without compromising durability or consistency. Its solutions align with growing global demand for sustainable polyester fibers used in textile yarns.

Future of rPET Fibers in Textile Yarns

Growing Demand for Sustainable Textiles

Consumer awareness and environmental regulations are accelerating demand for recycled materials across the textile sector.

Innovation in Recycling and Fiber Technology

Advanced processing techniques are improving fiber quality and expanding application possibilities.

Market Trends and Long-Term Outlook

As plastic bottle to polyester fibre solutions continue to evolve, recycled polyester fibers are expected to play a central role in the future of textile manufacturing.

Conclusion

Recycled PET fiber offers a practical and sustainable solution for modern textile yarns. It combines environmental responsibility with reliable performance across apparel, home, and industrial applications. By using recycled plastic bottles as raw material, manufacturers can reduce waste and meet sustainability goals without sacrificing quality. As demand for eco-friendly textiles grows, recycled PET fiber will remain a key material choice.

Frequently Asked Questions (FAQs)

1. Is recycled PET fiber suitable for high-quality textile yarns?

Yes, it offers strength, durability, and consistency comparable to virgin polyester.

2. How sustainable is recycled PET fiber compared to virgin polyester?

It uses less energy and reduces plastic waste, making it significantly more sustainable.

3. Can recycled PET fiber be used in apparel manufacturing?

Yes, it is widely used in sportswear, casual wear, and outerwear.

4. Is rPET fiber durable for long-term use?

The fiber maintains performance and structure over extended product lifecycles.

5. What industries benefit most from recycled PET fiber?

Textile, automotive, packaging, and industrial fabric sectors benefit the most.