Recycling plays a crucial role in preserving the environment and reducing the consumption of raw materials. The most frequently recycled material is Polyethylene Terephthalate also known as PET, it is often used while manufacturing bottles from plastic. PET is a material that, being lightweight, durable, but not overly complex in recycling makes it a boon to the circular economy we live in. About 60% of the PET bottles are recycled through an important step - conversion to PET flakes. These flakes can then be used to create new products, reducing waste and the demand for virgin plastic.

This blog looks at the environmental impact of PET bottles from their disposal to recycling them into PET flakes and the general effect.

What is PET Plastic?

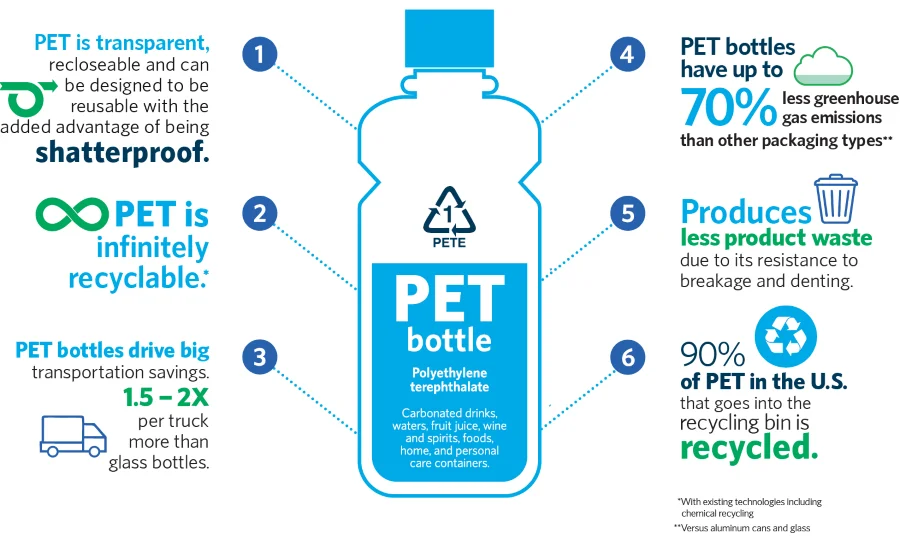

PET (Polyethylene Terephthalate) is a type of plastic commonly used for manufacturing beverage bottles, food containers, and other packaging materials. Due to its high mechanical strength, process transparency and ability to resist impacts, PET is appropriately one of the most commonly used packing materials with a niche in packing liquids such as water, soft drinks, juice, and household cleaners. Its popularity is due to its versatility, lightweight, and relatively low cost of production

PET bottles can be recycled again and again and are still able to deliver the same quality performance as before. Because of this feature PET is one of the most recycled plastics in the world. Apart from decreasing the throughput of virgin plastic, recycling PET saves the planet from the chaotic impacts of mismanaged plastic waste.

The Importance of Recycling PET Bottles

Recycling PET bottles is crucial for several reasons:

-

Waste Reduction: PET bottles contribute colossal amounts of plastics in the terrestrial, aquatic and other social systems. Marketing recycling as an activity assists in preventing these bottles from filling the waste streams and making contributions towards pollution.

-

Conserving Resources: Recycling PET means that there is less raw material required in the commercial production of PET products. Today, manufacturers turn the used PET bottles into flakes and reuse them instead of recycling creating a need for new plastics and other materials.

-

Energy Efficiency: Manufacturing of PET from post-consumer PET regrind, in the form of PET flakes, consumes considerably less energy than manufacturing virgin PET. Therefore, recycling PET conserves carbon emission plus brings down the energy required to manufacture plastics.

-

Creating Sustainable Products: Recycled PET flakes can be reused to manufacture new products like apparel and home textiles, flexible industries, automotive industry, and construction industries. This not only makes a contribution towards decreased production of new plastic but also helps in creating a sustainable economy.

The Process of Recycling PET Bottles into PET Flakes

It is important the material recovered from the PET bottles is of quality and suitable for reuse in new PET products, this is achieved by the following stages: Below are the key steps in the PET recycling process:

1. Collection and Sorting

Collection is the first stage of recycling petroleum ethylene terephthalate bottles. PET bottles are retrieved from collection points such as bins or stores and waste disposal facilities where customers dispose of their PET bottles. After the collection of the bottles they are taken to the recycling center.

Recycling facility the bottles are separated and cleaned from all sorts of contaminants like labels, cap or any other plastic, which is not PET. Sorting is sometimes manual, but it can also be helped by machines that employ special technologies such as the use of infrared sensors, air classification, or mechanical sorting. They want to make sure that only PET bottles make it to the next step of recycling, because recycling multiple types of plastics undermines the quality of the plastic produced.

2. Hot washing and decontamination

When the bottles are arranged, they go through a hot washing process. After sorting the bottles has been done. This stage affords the PET material a thorough wash in hot water to expunge any leftover labels, glue or any residues a previous content of the bottle may contain.

Hot washing also assists in improving the degree of purity of the PET material and confirming the suited quality. Occasionally, other chemical washing procedures may be applied which involve caustic or acidic solutions in order to eliminate a hard mold. This is one creative step because the type of material used, especially the PET, has to be clean in order to produce good quality bottles.

3. Drying and Separation

Afterwards, PET material is washed to ensure that any residual particles are removed from it, then it is left to dry in order to eliminate any moisture that is present. This is done using specialized drying machine or over that blows hot air over the material in order to dry it up. The drying process helps to avoid any presence of excessive water on the PET that may develop molds or bacteria once it accumulates.

It is often the case, especially within large facilities, that a process known as flotation separation may be carried out on the PET material. This range involves the use of water or air to sort a material from another depending on its density. For instance, PET material is heavier than paper or some plastics, but if it will sink at the bottom of a flotation tank a contaminant will float to the top of the tank and can be easily scraped off.

4. Packaging and Distribution

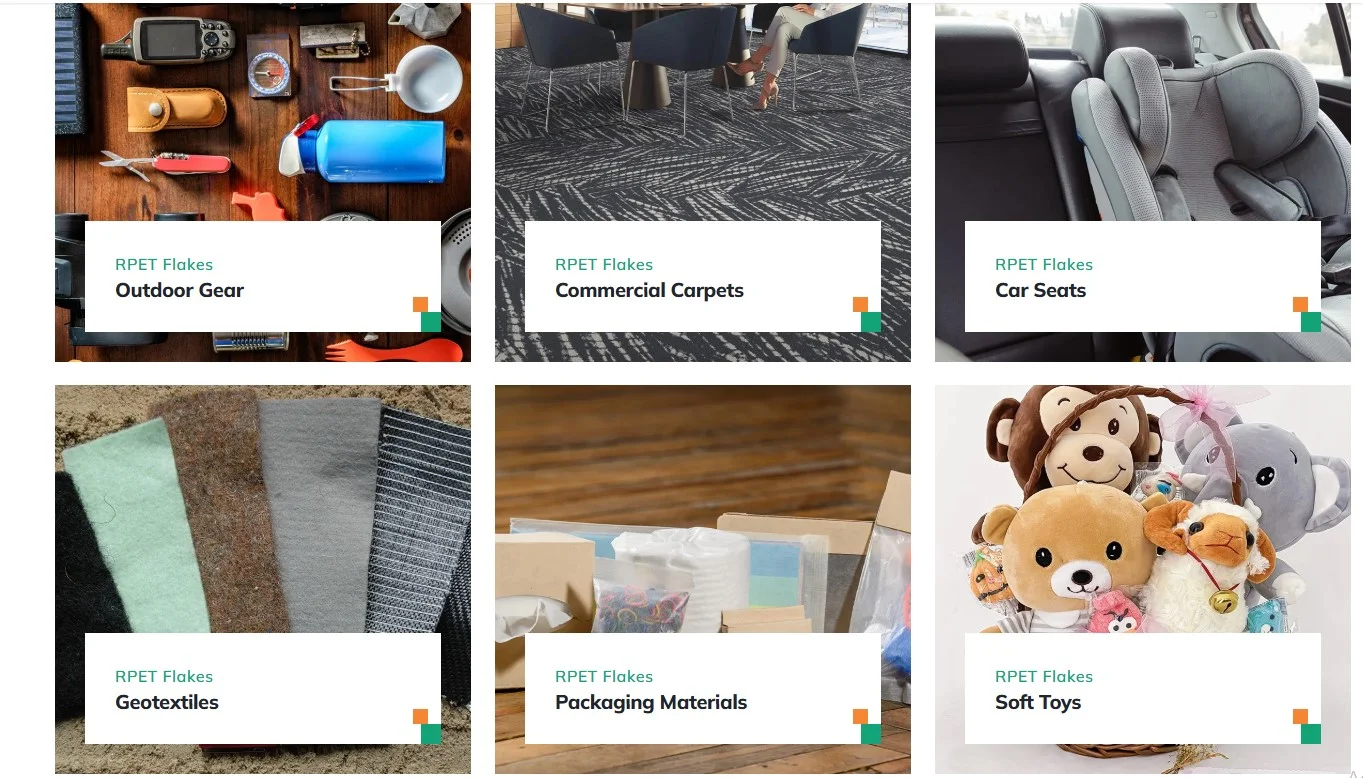

PET flakes are then packed and sold to companies for use in making new products out of the flakes. They can be textiles fibres and carpets, packaging materials, automotive parts or even new PET bottles etc. One of the majors was highlighted by the fact that recycling makes it possible for producers of PET products to develop numerous end products without using virgin polymer.

Applications of Recycled PET Flakes

Recycled PET flakes have a wide array of applications, including:

-

Textiles: Recycled PET is commonly used in the production of polyester fibers, which are used to make clothing, carpets, and upholstery. This reduces the demand for new polyester, which is derived from petroleum.

-

Packaging: Recycled PET flakes can be used to create new bottles or packaging materials. This is a prime example of the circular economy, where materials are recycled and reused to create new products.

-

Automotive Parts: Some automotive manufacturers use recycled PET flakes to produce car components such as bumpers, interior panels, and insulation materials.

-

Construction Materials: Recycled PET Material can also be used in the construction industry to create materials like insulation, roofing membranes, and other building products.

-

Consumer Goods: PET flakes can be used to manufacture a variety of consumer goods, including containers, toys, and household items.

Saheb Fiber: Top Exporter of RPET Flakes, RPSF & Colored RPSF

Saheb Fiber is amongst largest producer and Supplier of rPET flakes, RPSF( Recycled Polyester Staple Fiber) and Coloured RPF. Saheb Fiber attracts sustainable product development as it applies modern technologies and best practices to create high-quality recycled polyester range of products designed for textile, packaging and automotive industries. Infrastructure of dependent variables At present all the main facilities are highly equipped and qualified to provide clients environmentally sustainable products which are not less effective than the conventional products. Saheb Fiber has taken a great initiative to be an authorized recycler in Bangladesh where recycling of almost every sector is negligible and Saheb Fiber contributes well for recycling plastic wastes in case they are inevitable.

Conclusion

Recycling PET bottles into PET flakes is a crucial part of reducing plastic waste and promoting a circular economy. Collection of used PET bottles involves the sorting out of the bottles and then undergoing through various steps of cleaning, shredding and decontamination in order to produce clean and high quality flakes. These PET flakes which have been through this process can again be used in areas such as textiles, packaging, car components and construction.

People and companies should take an active part in the process of recycling so that they get an opportunity to minimize the amount of used plastics and contribute to the saving of limited resources.