Recycling of PET bottles can be defined as the process of converting used PET bottles into reusable material. It is an important process by which waste can be minimized and sustainable methods used. One of the most important acts to consider for environmental responsibility is the recycling of PET bottles. The Saheb Fibre Pvt. Ltd. based in Morbi, Gujarat has taken this initiative and converts the waste into utility products. In the following article, details of the recycling procedure of PET bottles are described, starting from the collection stage, through the production of recycled materials.

Life Cycle of PET Bottles and Procedure for Recycling Them

There are many steps that need to be done in an orderly manner for one to obtain a quality and usable product. Everyone is important in order to transform waste into useful products such as Recycled Polyester Staple Fibre (RPSF), Colored RPSF, RPET Flakes used in the textile industry, insulation, among others.

1. Collection of Used PET Bottles

The flow of recycling starts when people have used PET bottles and discarded them. These bottles are sourced from:

-

Households: Source; curbside recycling programs.

-

Businesses: Were collected from food outlets such as restaurants, holiday inn and shops.

-

Waste Management Facilities: Collected from the landfills and other mixed wastes.

Recycling process however starts with the accumulation of post-consumer pet bottles. These bottles are usually collected from recycling bins or from drop off centers. Deposit can be made through community programs or through a system where people are hired to return their bottles for deposits.

2. Sorting

The PET bottles disposed in litter bins are collected and thereafter taken to recyclers for sorting and inspection for recycling. This step involves:

-

Manual Sorting: Recycling employees sort PET bottles from these undesirable items and other types of plastics.

-

Automated Sorting: Hi-tech machines employ visioning systems that sort the PET bottles from the other wastes in the bin.

After that, they are transported to the recycling centres where they are sorted as per their kind. It entails sorting out PET bottles from other forms of plastics or materials that cannot be recycled. Plastic sorting can be carried out in a manual manner, or with the help of sorting systems that enhance recognition of plastics by their different resin types- as displayed by the recycling symbols on the bottles.

3. Cleaning and Pre-Washing

After sorting, Most of the bottles undergo a pre-wash process to wash off all the dirt, sand, other materials together with any remaining liquids. leaning process typically includes:

-

Pre-Washing: The bottles are washed to remove some debris on the outside to facilitate easy label stripping.

-

Chemical Washing: dissolve glue and evacuate solid raw material deposits.

-

Hot Water Washing: Any remaining residues are removed through rinsing of the bottles in hot water.

This is normally carried out using water jets along with tumbling machines, similar to washing machines, so that contaminants should not affect other processes.

4. Label and Cap Removal

Third, labels and caps are also often removed from bottles, if they have not already been deemphasis. This is necessary because labels could contain material that is of a different type of plastic that it is not possible to recycle.

Label crumbling machines fitted with cutting edges effectively peel labels off with a performance of up to 95%.

5. Shredding into PET Flakes

After washing, the PET bottles are crushed into small forms known as PET flakes. This is done using industrial shredders that reduce/convert the bottles into homogenous flakes. Shredding serves two purposes:

-

Reduces Volume: It is easier to transport and store flakes when compared to the pellets.

-

Prepares Material: Scrap is the most primary material in making recycled goods and is produced in the form of flake.

The bottles are then washed removing the label and the bottles are then crushed into small particles or flakes using shredding machines. This makes it easier to clean further and in later stages to process because it provides a larger surface area of the material.

6. Further Cleaning & Washing

After shredding, the different flakes produced are extensively washed in order to remove any glue residues, dirt or any other off materials.

Water Baths: Different density PET materials are floated or sink while other materials that are not made from PET are separated.

It can also include scrubbing with warm soapy water and or detergents several times.

7. Flake Sorting & Separation

After washing, PET flakes may still contain impurities such as tiny particles of glue or non-PET materials. Advanced separation techniques are used at this stage:

-

Air Separation: WG light impurities are removed with air streams.

-

Magnetic Separation: Metals are separated with the aid of a magnet in the removal of the contaminants.

This sorting is important since it eliminates all other materials which are not PET, to reduce contamination of the recycled product.

8. Drying

After sorting the flakes are either sun-dried or dried by convection, in order to remove moisture present in them. This is the final step necessary for preparation of the flakes to undergo the process of melting and pelletizing.

9. Melting and Extrusion

The dried PET flakes are put in controlled chambers which causes meltdown of the flakes to a homogeneous polymer. It is then extruded from the molten PET form into either strands or pellets. This step is highly versatile and produces materials that can be used in various ways:

-

Strands: Its uses include generation of fibers for purposes such as the production of Rayon, Polyester, Silk and Fiber (RPSF).

-

Pellets: As the inputs in the production of new PET products for bottle and packaging.

The resulting dried PET flakes are in turn processed for what can be termed as pelletizing whereby the material is turned into small pellets through melting. These pellets act as a base before manufacturing new and different products such as new PET bottles or other products made of plastic.

10. Manufacturing New Products

The last stage in the receiving and recycling process involves the transformation of post-consumer extruded PET into products. Common products made from recycled PET include:

Recycled Polyester Staple Fibre (RPSF):

RPSF is a universal material for further use in textile, thermal and sound insulations and industrial cushioning. This is made from recycled PET bottles and waste and has become cheaper and environmentally friendly than virgin polyester used in clothing, bedding and insulation.

Colored Recycled Polyester Staple Fibre (Colored RPSF):

Colored RPSF has all the attributes of RPSF but the major plus being that it comes in different colors. This product will be useful to fashion and home décór industries since it eliminates the need to take extra dyeing procedures.

RPET Flakes:

RPET flakes are thus derived from the PET bottles that go through the recycling process. These are clean flakes that are utilized in the manufacture of textiles, packaging, and even new plastic products hence, there’s minimal usage of virgin plastic.

At Saheb Fibre, we are dedicated to providing high-quality recycled products that support a sustainable future across industries.

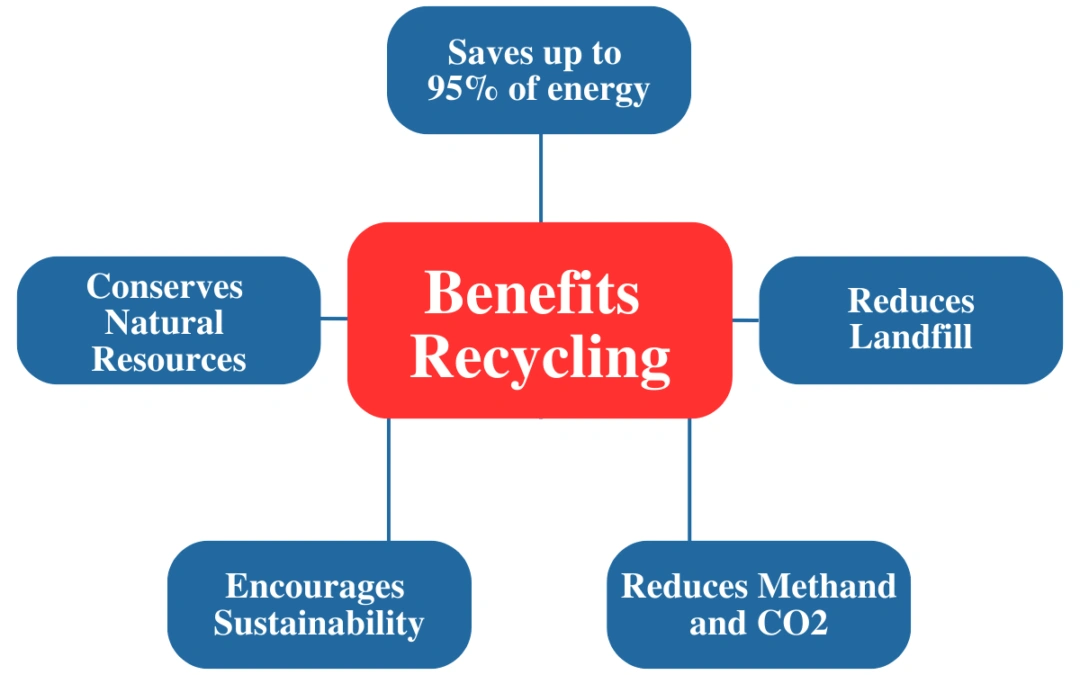

Environmental Benefits of PET Recycling

There are many environmental benefits to recycling PET bottles:

-

Decreases Plastic Waste: Reduces plastic that ends up in our oceans and landfills.

-

Conserves Energy: It takes much less energy to produce recycled PET than virgin PET.

-

Saves Resources: Essential to the production of plastic, it decreases the usage of petroleum, a non-renewable resource.

-

Reduces Pollution: Pollution is minimized with recycling compared to creating everything from scratch.

PET recycling brings it into harmony with global efforts to fight climate change and to meet sustainability goals.

Challenges in PET Recycling

Despite its benefits, PET recycling faces challenges, such as:

-

Contamination: Contamination and using other plastics which are not PET type makes recycling to be an unproductive process.

-

Economic Viability: This means that where virgin PET prices are lower than virgin PET prices the recycled materials will not be in high demand.

-

Technological Limitations: High technology methods for sorting and processing are expensive to deploy.

To overcome these challenges the cooperation between governments, industries and consumers is mandatory.

Conclusion

The recycling of PET bottles consists of several carefully prearranged procedures aimed at the reduction of contamination. Through the conversion of those plastic bottles into flexible forms, we help solve environmental issues, and in the same process offer industries sustainable options for their raw materials. Saheb Fibre is working towards this sustainable purpose because one bottle recycled means a planet on the go and a green tomorrow!! Let us make recycling more than a process, but a way of life!