The automotive industry is rapidly shifting toward sustainable materials, and recycled polyester staple fiber (RPSF) is playing a key role in this transition. Derived from post-consumer waste like polyester bottles, RPSF helps manufacturers reduce environmental impact without compromising performance. From vehicle interiors to insulation layers, its use is expanding across multiple applications.This blog explores how this recycled fibre supports modern automotive needs, its key benefits, and where it is most commonly used.

What Is RPSF and Why Is It Important for Automotive Applications?

Understanding Recycled Polyester Staple Fiber

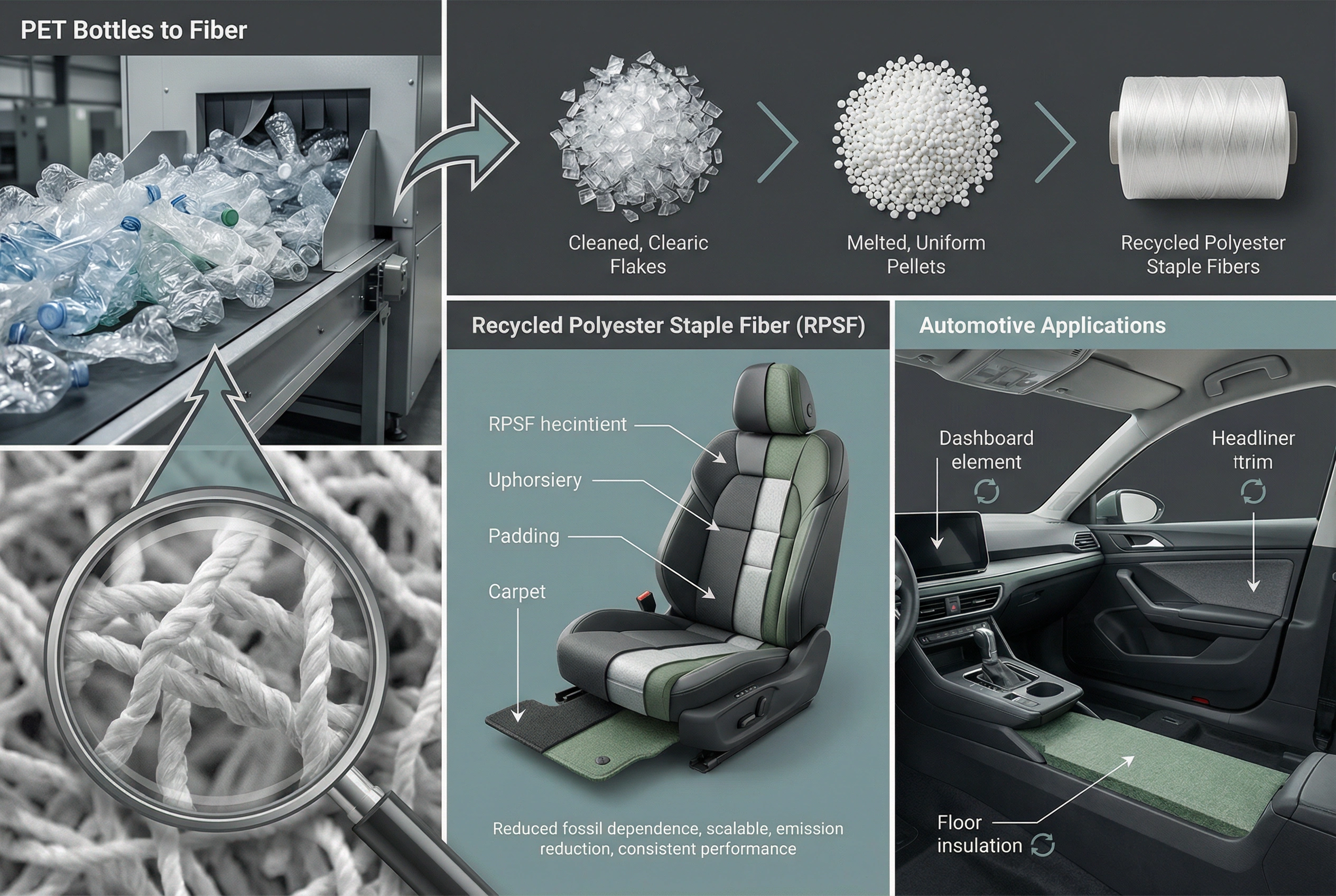

Recycled polyester staple fiber is a synthetic fiber produced from recycled PET materials, mainly discarded polyester bottles. These bottles are processed into recycled polyester fiber through cleaning, melting, and fiber extrusion. The result is a versatile material that mirrors the performance of virgin polyester while reducing dependence on fossil-based raw materials.

Role of RPSF in Sustainable Automotive Manufacturing

Automotive manufacturers face increasing pressure to lower emissions and adopt circular economy practices. Using post-consumer polyester materials helps reduce landfill waste and energy consumption. RPSF supports sustainability targets while maintaining the durability, consistency, and scalability required for mass vehicle production.

Key Properties That Make This Fibre Suitable for Automotive Use

This recycled fibre is widely adopted because it balances performance with sustainability.

Key properties include:

-

High tensile strength and structural stability

-

Excellent durability for long-term vehicle use

-

Lightweight nature supporting fuel efficiency

-

Effective thermal and acoustic insulation

-

Resistance to moisture and chemicals

-

Cost efficiency compared to virgin materials

These characteristics make recycled PSF a reliable choice for both interior and functional automotive components.

Major Automotive Applications of Recycled Polyester Fibre

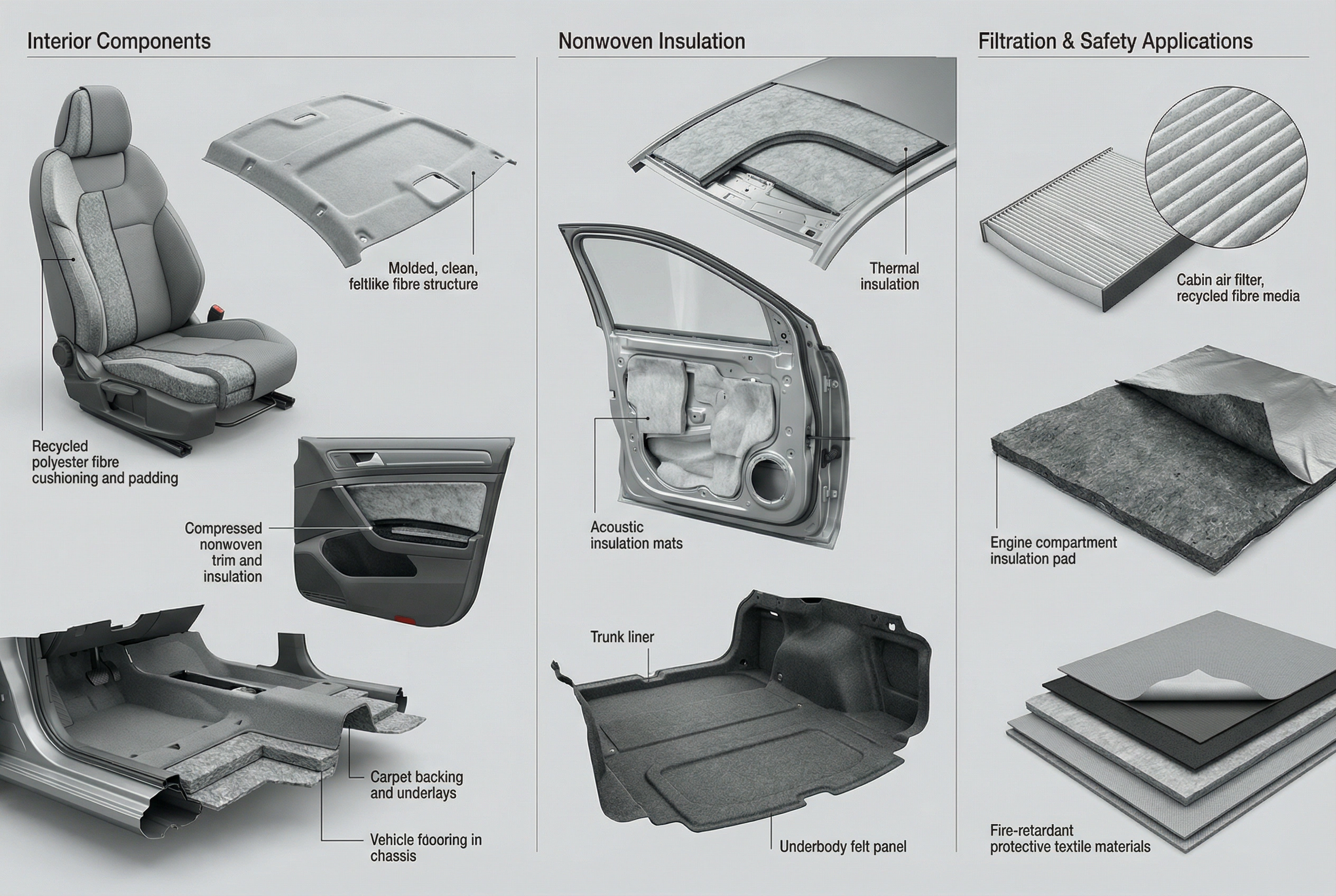

Use in Automotive Interior Components

The fibre is commonly used in vehicle interiors where comfort, resilience, and aesthetics matter.

-

Seat padding and cushioning layers

-

Headliners and roof liners

-

Door panels and interior trims

-

Carpet backing and floor underlays

Its adaptability allows manufacturers to mold and layer fibers for different design and performance requirements.

Use in Automotive Nonwoven Applications

Nonwoven textiles made from recycled poly fabric are widely used for insulation and protection.

-

Acoustic insulation mats to reduce cabin noise

-

Thermal insulation layers for temperature control

-

Trunk liners and underbody felts

These applications benefit from its ability to absorb sound while remaining lightweight.

Use in Filtration and Safety Products

Beyond comfort, recycled PSF also supports functional and safety-related uses.

-

Cabin air filtration media

-

Engine compartment insulation pads

-

Fire-retardant and protective textile layers

Here, recycled polyester fabric delivers consistent fiber structure and reliability.

Comparison Table – RPSF vs Virgin Polyester Fibre

|

Feature |

Recycled Polyester Staple Fiber |

Virgin Polyester Fibre |

|

Raw material source |

Recycled polyester bottles |

Petrochemical-based |

|

Environmental impact |

Low carbon footprint |

High carbon footprint |

|

Cost efficiency |

More economical long term |

Higher raw material cost |

|

Performance |

Comparable durability |

High durability |

|

Sustainability rating |

High |

Low |

|

Automotive suitability |

Excellent |

Excellent |

This comparison highlights why sustainable fibre options are increasingly preferred in automotive manufacturing.

Benefits for Automotive Manufacturing

Using this recycled fibre offers multiple advantages across the supply chain:

Environmental benefits

-

Reduces plastic waste

-

Lowers energy and water usage

Cost advantages

-

Stable pricing compared to virgin polyester

-

Reduced material dependency risks

Lightweight performance

-

Supports better fuel efficiency

-

Helps reduce vehicle emissions

Consistent quality

-

Uniform fiber properties

-

Suitable for large-scale production

Regulatory alignment

-

Supports ESG goals and OEM sustainability mandates

About Recycled Fibre Use in Automotive Applications

Why is RPSF preferred over virgin polyester in automotive interiors?

The material offers similar durability and comfort while significantly reducing environmental impact. Its ability to meet performance standards makes it a sustainable alternative without sacrificing quality.

Is RPSF durable enough for long-term automotive use?

Yes, recycled synthetic fibre undergoes strict quality control and testing. When processed correctly, it delivers long-lasting performance suitable for extended vehicle lifecycles.

How does RPSF help reduce vehicle weight and emissions?

Lightweight structure supporting fuel efficiency yet strong, which helps lower overall vehicle weight. Reduced weight improves fuel efficiency and contributes to lower carbon emissions.

Challenges & Considerations When Using Recycled Fibres

Quality Consistency

Uniform raw material sourcing is critical for stable fiber performance.

Supplier Reliability

Automotive manufacturers must work with experienced suppliers who maintain strict quality controls.

Application-Specific Fibre Selection

Different components require specific fiber properties such as denier, cut length, and bonding behavior.

Future Trends in Sustainable Automotive Fibres

-

Increased recycled content mandates

-

Lightweight materials for electric vehicles

-

Advanced non-woven recycled poly fabric innovations

The demand for sustainable synthetic fibres is expected to grow steadily as sustainability becomes central to vehicle design.

Sustainable Automotive Fibre Solutions by Saheb Fibre

Saheb Fibre is a trusted manufacturer of recycled polyester staple fiber and rPET flakes, supplying high-quality materials for textile and industrial applications. With a strong focus on sustainability, consistent quality, and responsible sourcing, the company supports automotive manufacturers in achieving performance and environmental goals. Its recycled polyester solutions are designed to meet evolving industry standards.

Conclusion

RPSF has become a practical and sustainable material choice for modern automotive applications. Its versatility, durability, and environmental benefits make it suitable for interiors, insulation, and functional components. As the industry continues to prioritize sustainability, recycled polyester staple fiber will play an even more important role in automotive manufacturing decisions.

Frequently Asked Questions (FAQ)

1. What is RPSF used for in automobiles?

RPSF is used in interiors, insulation mats, carpet backing, and filtration components.

2. Is recycled polyester eco-friendly for automotive use?

Yes, it reduces plastic waste and lowers carbon emissions compared to virgin materials.

3. Can recycled polyester replace virgin polyester completely?

In many applications, it can, depending on performance and design requirements.

4. Does recycled polyester affect vehicle performance?

No, when properly engineered, it maintains durability while improving sustainability.