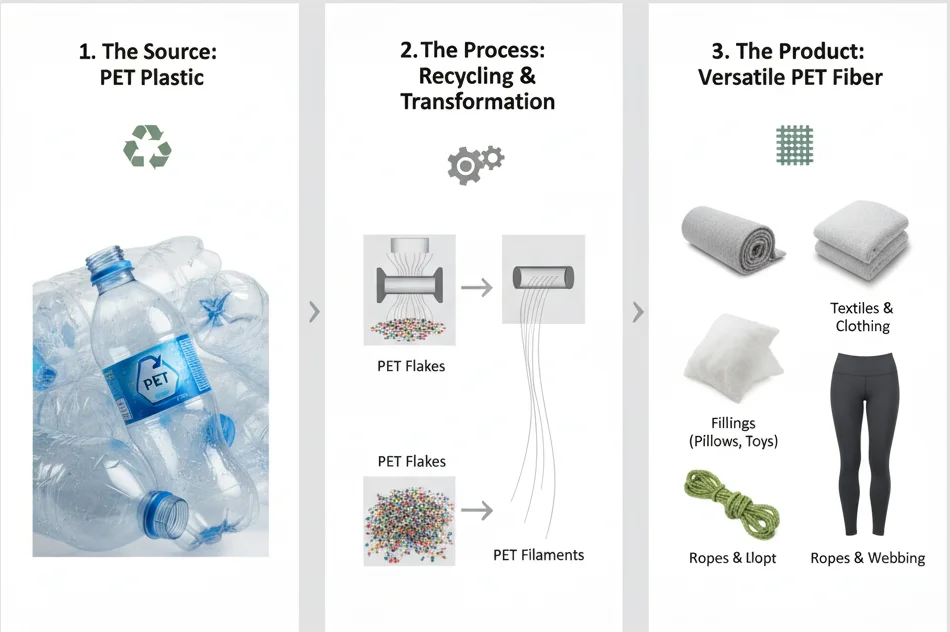

Over the past few years, brands in textiles, packaging, and other industries have started moving toward PET fiber. PET stands for polyethylene terephthalate, a type of plastic. It is most commonly known as the material used for pet bottles. But in fiber form, PET has a wide range of applications, from fabrics to industrial products.

So why are companies making this shift? The answer is a mix of environmental concerns, cost considerations, and product versatility. Here’s a closer look at the trends and benefits driving this change.

What is PET Fiber?

PET fiber is a synthetic fiber made from recycled polyethylene terephthalate. It is often referred to as rPET when recycled. These fibers can be spun into threads, woven into fabrics, or used in non-woven materials. PET fiber has some notable characteristics:

-

It is strong and durable.

-

It resists wrinkles and shrinking.

-

It dries quickly and holds color well.

-

It is recyclable when processed properly.

These qualities make PET fiber attractive for various industries.

Cost Benefits for Brands

PET fiber can save money in several ways. First, the raw material often costs less than new polyester. Recycling plastic reduces material costs while keeping quality consistent.

Second, using PET fiber can reduce production expenses. Modern recycling and fiber-making processes are efficient. They allow manufacturers to produce large volumes without a significant increase in cost.

Third, switching to PET fiber can lower waste management costs. Brands that produce less waste or reuse plastics internally can avoid disposal fees.

These savings are not massive for every company, but over time they add up. For many brands, the financial benefits align with environmental goals.

Durable and Versatile Material

PET fiber is strong and long-lasting. Fabrics made from it resist wear and tear. That makes it ideal for clothing, bags, and home textiles.

It also holds dyes well. This allows brands to offer a wide range of colors without compromising quality. PET fiber doesn’t shrink easily, and it dries fast. For products like sportswear or outerwear, these features are important.

Beyond clothing, PET fiber is used in carpets, upholstery, and industrial applications. Its versatility means brands can use it across multiple product lines.

Consumer Demand is Shaping Choices

Consumers are influencing how brands source materials. Many shoppers now ask where a product comes from and how it is made.

PET fiber appeals because it is recycled. People feel they are making a better choice when they buy products made from recycled plastic. It’s not perfect, but it’s a step toward reducing waste.

Some consumers are also looking for products that last longer. Since PET fiber is durable, it fits this need. It offers a balance between sustainability and practicality.

Brands that adopt PET fiber can market their products honestly. They can say the fiber comes from recycled materials without exaggerating. Transparency resonates with modern buyers.

Easy Integration into Manufacturing

PET fiber can be used in existing textile machinery. This reduces the need for major investments. Brands don’t have to overhaul production lines to start using it.

It can be blended with other fibers too. Cotton-PET or wool-PET blends are common. This allows brands to maintain comfort, texture, or style while increasing sustainability.

The fiber’s consistency is another advantage. Unlike some recycled materials that vary in quality, PET fiber is uniform. That makes it predictable for manufacturing and quality control.

Supporting Circular Economy Goals

A circular economy focuses on keeping materials in use as long as possible. PET fiber fits neatly into this idea.

By turning plastic bottles into fiber, brands give waste a second life. At the end of the product’s life, some PET fabrics can be recycled again. This loop reduces the reliance on virgin materials.

Companies with sustainability goals can show measurable progress by adopting PET fiber. It’s a concrete step toward reducing environmental impact.

Branding and Reputation Benefits

Switching to PET fiber is also a reputational advantage. Consumers notice when brands take visible steps toward sustainability.

But honesty matters. Overstating environmental claims can backfire. Brands that simply use recycled PET and explain it clearly can build trust.

And in certain industries, eco-friendly practices are becoming standard. Not adopting sustainable materials could make a brand seem outdated.

Emerging Trends in PET Fiber Usage

The use of PET fiber is expanding beyond basic textiles. Some trends include:

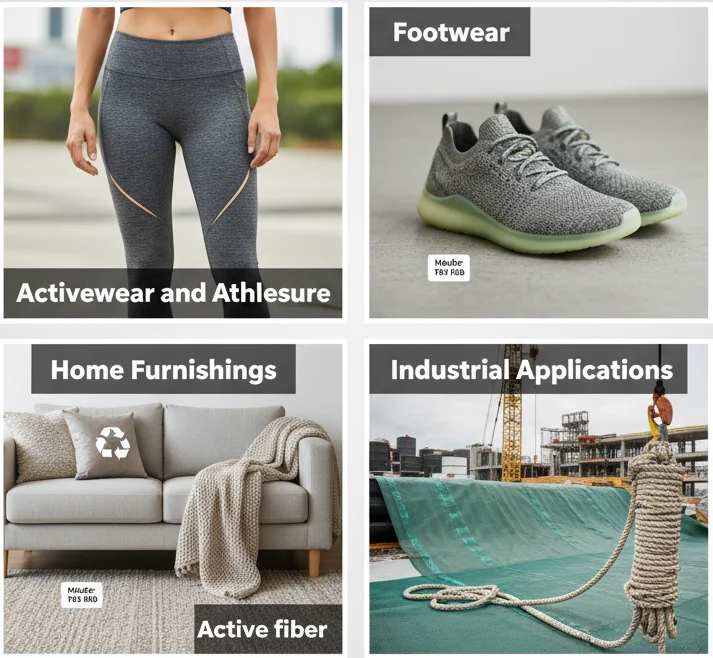

- Activewear and athleisure: These markets need strong, moisture-wicking fabrics. PET fiber blends work well.

- Footwear: Some sneakers and casual shoes now include PET fibers in fabrics and linings.

- Home furnishings: Carpets, rugs, and cushions are increasingly made with recycled PET fiber.

- Industrial applications: Insulation, automotive fabrics, and packaging materials are adopting PET fiber for durability and cost-efficiency.

The diversity of applications shows that PET fiber is not just a niche material. It’s becoming mainstream.

Challenges to Consider

PET fiber is not perfect. There are some challenges brands should know:

- Microplastics: Washing PET fabrics can release tiny plastic particles into water systems. Brands need to consider ways to minimize this.

- Feel and comfort: Pure PET may feel less soft than natural fibers. Blending can help, but it’s not always ideal for premium clothing.

- Consumer skepticism: Some shoppers may be wary of recycled plastics. Clear communication is key.

Brands that address these challenges openly can maintain credibility. It’s better to be honest about limitations than overpromise.

The Future Outlook

The use of PET fiber is likely to grow. Governments are implementing stricter plastic regulations. Consumers continue to demand sustainable products.

Technology for recycling is improving too. Advanced methods allow better fiber quality and reduced environmental impact.

Brands that adopt PET fiber early may gain a practical edge. They can learn to integrate it efficiently and address consumer concerns.

And as more companies switch, the cost of recycled PET fiber may decrease further. This could make it accessible to even more businesses.

Conclusion

Brands are switching to PET fiber because it meets practical needs and sustainability goals. It reduces plastic waste, lowers costs, and creates durable products. Consumers notice and appreciate the effort. There are challenges, like microplastics and comfort issues, but these can be managed with proper techniques and transparency.

PET fiber is not a perfect solution, but it is a useful step toward more responsible production. For brands, it’s a way to act on environmental concerns while still creating products people want. In the end, using PET fiber is about balance. It’s about reducing waste, cutting costs, and offering quality products all while being honest with consumers.

At Saheb Fibre, we are proud to contribute to this transition by delivering high-quality recycled PET solutions that align with modern business values and consumer expectations. The shift toward PET fiber is not just a trend it’s a step toward building a more sustainable and responsible future