Today, the industries are looking for more effective and eco-friendly material. rPET (recycled polyethylene terephthalate) is one standout material leading this green revolution. rPET is widely known for its role in electronics and food packaging and automotive industry, but is now beginning to shine as a leading industrial solution for its incredible durability, affordability and sustainability credentials.

In this article, we look at what are the best reasons why rPET is the best option when it comes to industrial applications, benefits, drawbacks, and what is its role in manufacturing’s future.

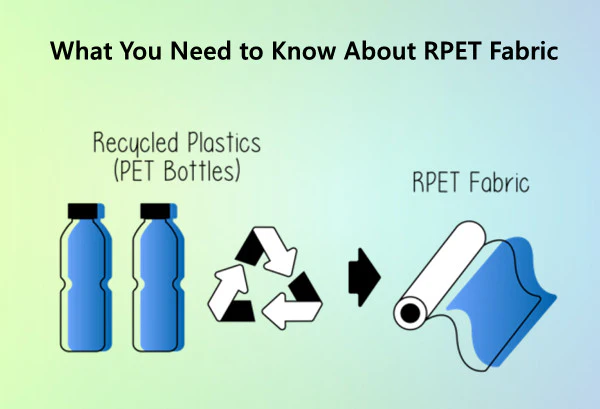

What is rPET?

rPET stands for recycled polyethylene terephthalate. It’s made by used PET plastics, such as water bottles, into new, reusable materials.

How rPET is Made:

-

Collection of used PET containers.

-

Cleaning and sorting.

-

Mechanical or chemical recycling into pellets or flakes.

-

Re-manufactured into new products.

Top Reasons to Choose rPET for Industrial Applications

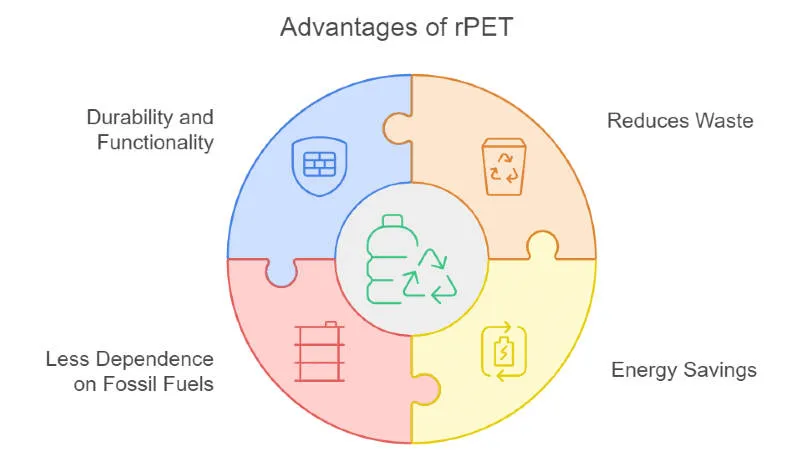

1. Comparable Quality to Virgin PET

Advanced recycling processes such as chemical or enzymatic recycling can provide rPET with properties that are the same as virgin PET. These methods are used to produce output with high quality, which are suitable applications for food packaging and automotive components. The chemical recycling of PET breaks the plastic into monomers from which new PET with standard strength, durability and clarity can be made.

2. Cost Efficiency

rPET offers a cost-effective alternative to virgin PET. Recycled materials are available, decreasing raw material costs, making it an economical alternative for industries.

3. Regulatory Compliance and Safety

Under stringent global standards, rPET is a safe and reliable industrial material. This is ISO environmental standard compliant and is often certified by Global Recycled Standard (GRS) and BSI certification that verifies recycled content, traceability and responsible environmental operation along the supply chain.

4. Technological Advancements

Innovative recycling technologies enhance the feasibility of using rPET:

-

Mechanical Recycling: Meeting efficiency standards of producing high quality pellets for industrial use

-

Chemical Recycling: Chemical Recycling converts PET waste to high value raw pre-polymers similar to virgin PET.

-

Enzymatic Recycling: Offers a sustainable method with lower energy requirements and high-quality output potential.

Industrial Applications of rPET

Some of the common sectors that make use of rPET include:

-

Packging: Food packaging; soft drink bottles; food containers especially thermoformed, and trays.

-

Textiles: Fibers and fabrics for clothing, carpets, and upholstery.

-

Construction: Geotextiles, insulation products, and carpet backings.

-

Automotive: Interior components like seat upholstery, acoustic insulation, and floor carpets.

Its ability to be molded into various forms makes it suitable for diverse industrial needs.

Environmental Benefits of rPET

-

Circular Economy: rPET has this particular strength in that it cuts down on the use of virgin PET and appeals to sustainability initiatives.

-

Environmental advantage: The generation of rPET also has a lower energy intensity and involves the emission of fewer greenhouse gases than virgin PET production.

-

Environmental Conservation: Recycling of PET results in the reduction of plastic wastes that are dumped in landfills and the seas.

Challenges of Using rPET in Industry

Despite its benefits, rPET adoption isn’t without obstacles:

-

Supply Chain Variability: Quality and availability can fluctuate.

-

Contamination: Non-PET plastics or food residues can affect material properties.

-

Initial Setup Cost: Adapting manufacturing lines to process rPET can be capital-intensive.

Final Thoughts

Whether it be an automotive company, packaging manufacturer, construction materials provider, or textile maker, adopting rPET does not just benefit the ecosystem, it makes business sense. Hence, making rPET the go-to material of choice for modern industrial applications as it comes with more benefits in terms of performance, cost and sustainability than most other materials.

We at Saheb Fibre manufacture, export and supply Recycled Polyester Staple Fiber RPSF, Colored RPSF, PET flake, for modern day’s demanding industries and sectors. Get to know our recycled PET products and find out how your business can benefit from sustainable solutions.