Recycled Flakes made of recycled PET (Polyethylene Terephthalate) have become functional to sustainable systems within various industries whereby its contributions are hardly acknowledged in the mainstream sources. When we look at creating a greener future, it is important that businesses and consumers understand how the recycling process of PET works and what applications exist.

What Are Recycled PET Flakes?

The recycled PET flakes are made of post-consumer PET products, including packaging materials and plastic bottles. The process of collection, sorting, cleaning, and shredding of these wastes is meticulous thus adding them to produce high quality raw materials used to make new products. rPET is a powerful story of change: of transforming liabilities into the raw materials of a circular economy.

How Are Recycled PET Flakes Made?

Here’s a step-by-step breakdown of the rPET Flakes production process:

-

Collection: Collected used PET products (such as plastic bottles) are gathered via the recycling bins, waste facilities or industrial sources.

-

Sorting: PET waste is sorted so that it can be separated with other plastics and other materials.

-

Cleaning: The sorted PET is then thoroughly cleaned by being washed to remove labels, adhesive, food residues and other contaminants.

-

Shredding: The PET is then shredded mechanically into minute flakes, which is termed as clean PET.

-

Separation: Flakes are then cleaned and separated according to their density in order to remove any forms of impurities such as caps or labels.

-

Drying: The rPET flakes are dried out to minimize the amount of moisture and proceed further.

-

Final Processing: Raw flakes which are new products, across industries.

It is beneficial in preserving resources, limiting landfill waste, and, unlike virgin plastics, decreasing the carbon footprint.

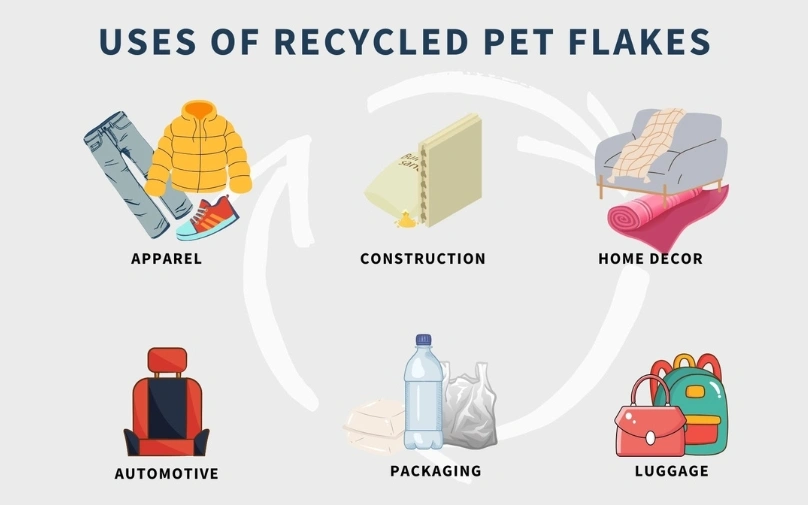

Where Are Recycled PET Flakes Used?

1. Textile Industry

The textile industry that has always had a stained reputation in terms of environmental degradation has also welcomed recycled PET flakes as a strategy towards becoming more environmentally friendly by utilizing more recycled products rather than the traditional polyester yarns. The key brands are now involved in the production of goods containing rPET fibers, as the population requires environmentally friendly and ethically produced products.

2. Packaging Solutions

As more people become aware of the problem of single-use plastics, the packaging industry has found an effective solution in rPET as a sustainable solution. Recycled PET flakes have been put in the production of food containers, cosmetic packaging, electronic casing to provide a green choice that lacks the without compromising of quality or safety.

3. Automotive Components

The automotive sector utilizes rPET in interior components such as carpets, seat fabrics, and insulation materials. This adoption is significant in an industry traditionally associated with high resource consumption and waste generation.

The rPET is used in the car features, including the car carpets, seat fabrics, plastic items, insulation materials, etc. This adoption is meaningful in an industry that is used to be dependent on extensive use of the resources and generation of waste.

4. Construction and Building Materials

Recycled PET flakes find a crucial application in the construction industry, as they can be used in insulation boards, roofing shingles, etc. With the use of rPET, it is possible to limit the shrinkage of waste using virgin plastics and thus contribute to sustainable growth.

5. Everyday Consumer Goods

rPET is found across a variety of customer products, whether it be household goods and furniture or electronic accessories. Producers give customers the opportunity to be responsible in environmental decisions and not compromise functionality and aesthetics.

Why Is Awareness About Recycled PET Flakes Important?

Although recycled PET flakes are used widely in most of our daily activities, we mostly end up without acknowledging its role. This ignorance continues the process of environmental destruction and unreasonable consumerism. Consumers can also be involved in sustainability and circular economy by learning about and purchasing products manufactured using recycled materials.

How Do Recycled PET Flakes Support the Circular Economy?

Recycled PET flakes are a powerful example of circular economy principles, where waste is repurposed instead of discarded.

-

Keeps plastic in use and out of landfills

-

Conserves resources and energy

-

Reduces environmental pollution

-

Encourages manufacturers to design recyclable products

Every rPET-based product represents a shift away from linear, wasteful production and toward long-term sustainability.

What Makes rPET the Future of Plastic Manufacturing?

The growing adoption of rPET flakes is fueled by several compelling factors:

-

Circular Economy Enablement: rPET prevents plastic waste and allows using it as part of a circular economy.

-

Decreased environmental degradation: Producing products using recycled PET consumes lower energy and low amounts of greenhouse gases.

-

Regulatory Push: The policies including Extended Producer Responsibility (EPR) and governments are pushing an industry toward recycled content.

-

Consumer Awareness: Customers are becoming more interested in seeking additional sustainable options, and this makes the rPET-based products commercially viable.

What Can Consumers and Industries Do to Promote rPET?

-

Select rPET Products: Use products whose labels say that they are made of recycled PET to lower the carbon footprint and engage in sustainable practices.

-

Champion Change: Push policy and sectors to focus on sustainability and direct energy on green and sustainable options.

-

Spread Awareness: Inform people on the concept and use of rPET to encourage them to adopt it on the collective level to create a change.

How Saheb Fibre Is Leading the Charge

The case of Indian manufacturers of Recycled Polyester Staple Fiber and rPET flakes like Saheb Fibre shows how innovation can drive sustainability. Recycled fibers made out of millions of used plastic bottles turn into sustainable products, which makes a difference.

The idea of sustainable manufacturing is not the only sign of environmental responsibility by them, it is also a future of modern manufacturing representative where quality meets conscience.

Conclusion

The recycled PET flakes are not only waste management by-products; they are a way to appreciate innovation, sustainability, and mass motivation. RPET can help us escape an endless cycle of consumption that has become too close to our hearts and create a new future where we place importance on progress and the planet as they are equally valuable.

It’s time we recognize and support this silent revolution. By choosing products made from RPSF, Colored RPSF, rPET flakes manufacturers like Saheb Fibre, we take a powerful step toward a greener, more responsible future.

Frequently Asked Questions (People Also Ask)

1. What are the main applications of recycled PET flakes?

Recycled PET flakes are used in textiles, packaging, automotive components, construction materials, and various consumer goods1.

2. How do recycled PET flakes contribute to sustainability?

They reduce landfill waste, conserve resources, and lower the carbon footprint compared to virgin plastics, supporting a circular economy1.

3. Are products made from rPET as durable as those from virgin PET?

Yes, products made from recycled PET flakes maintain high quality and functionality, making them a viable alternative to conventional plastics1.

4. How can I identify products made from recycled PET?

Look for certifications or labels like “Made from rPET” and buy from brands with transparent sustainability practices.