The recent trend across the world in the direction of sustainable manufacturing has transformed the manner in which various industries procure materials, and PET plastic flakes have become the bedrock of the circular economy. The polyethylene bottles pieces, which comprise the recycled PET bottles and containers, are revolutionizing the various industries at the same time, saving on production costs and harming the environment.

What Are PET Flakes and Why Do Industries Choose Them?

PET flakes are pieces of recycled polyethylene terephthalate plastic, in the form of small, clean pieces acquired via PET flakes recycling. These rPET flakes are cleaned, sorted and processed extensively to achieve industrial standards of quality. PET bottle flakes have become more popular in the industries partly because they are relatively low-cost and environmentally friendly and have numerous applications in many manufacturing industries.

The PET flakes market has gained momentum and this has been attributed to the rise in the level of environmental concern, government policies encouraging recycling and the fact that recycled materials are cheaper than virgin plastics.

1. Textile and Apparel Industry: Leading PET Flakes Applications

Polyester Fiber Production

The largest consumer of PET flakes as raw material is the textile industry and most of the big brands are already producing lines of products made with recycled polyester. The textile uses of PET flakes are:

-

Performance sportswear and activewear: Leading athletic brands use recycled PET flakes to create moisture-wicking fabrics

-

Fashion apparel: Fast fashion and luxury brands integrate recycled polyester for sustainable clothing lines

-

Home textiles: Carpets, upholstery, and bedding manufacturers utilize PET flakes for durable textile production

-

Technical textiles: Industrial fabrics for automotive, construction, and medical applications

Sustainability Impact:

By recycling 10 clear plastic bottles, there is sufficient material to make a T-shirt or soccer jersey, which translates considerably to the use of virgin polyester and fossil fuels.

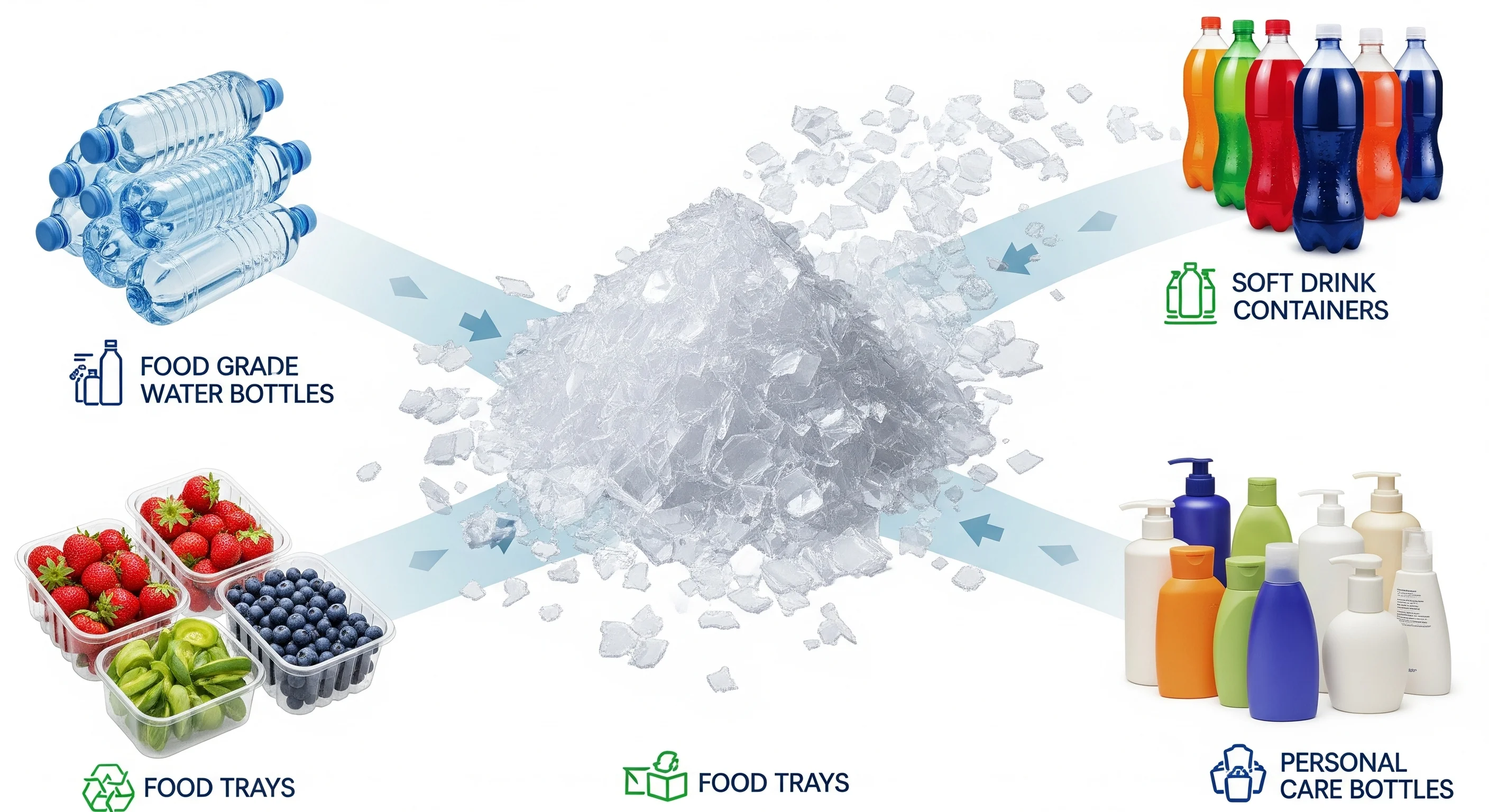

2. Packaging Industry: Circular Economy Champion

Food and Beverage Packaging

PET flakes are widely used in the packaging industry as part of the process of making new containers and bottles. Important applications are:

-

Food-grade PET bottles: Recycled content in water bottles, soft drink containers, and juice packaging

-

Food containers and trays: Thermoformed packaging for fresh produce, bakery items, and prepared foods

-

Barrier packaging: Multi-layer packaging films incorporating recycled PET flakes for extended shelf life.

-

Cosmetics and Personal Care Packaging: Traditionally, beauty and personal care brands use PET bottle flakes packages to satisfy consumer demand for sustainable products. They are used in shampoo, lotion bottles, and cosmetic bottles.

Sustainability Impact:

Bottle flakes are used in packaging and thus contribute less to greenhouse emissions and facilitate circular economy towards product packages.

3. Automotive Industry: Engineering Excellence with Recycled Materials

Interior Components

The automotive sector leverages PET flakes for automotive applications in various interior components:

-

Seat fabrics and upholstery: Durable, stain-resistant textile materials

-

Carpet and floor mats: Sound-dampening and wear-resistant automotive carpeting

-

Door panels and trim: Injection-molded components using recycled PET compounds

-

Insulation materials: Thermal and acoustic insulation applications

-

Under-the-Hood Applications: Engineering grade hot wash PET flakes are used in non-critical automotive parts such as air filter housings, fluid reservoirs and protective covers.

Sustainability Impact:

Incorporation of PET flakes in cars creates a low environmental impact of the vehicle and the overall shift of the automotive industry to cleaner operations.

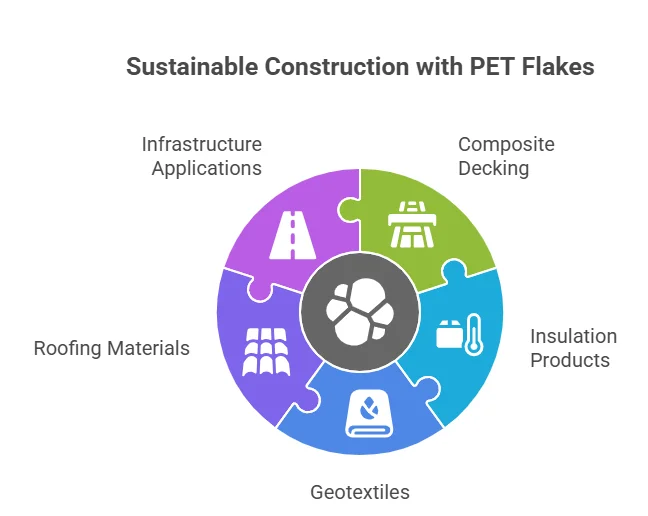

4. Construction and Building Materials: Sustainable Infrastructure

Composite Materials and Panels

The construction industry utilizes PET flakes construction materials for:

-

Composite decking: Weather-resistant outdoor decking combining PET flakes with wood fibers

-

Insulation products: Thermal insulation materials for residential and commercial buildings

-

Geotextiles: Drainage and filtration materials for civil engineering projects

-

Roofing materials: Weather-resistant roofing components and membranes

-

Infrastructure Applications: The recycled PET bottles is also used in construction to make roads as the PET flakes increase the durability of asphalt and make it eco-friendly.

Sustainability Impact:

The PET-based materials made through recycling meet a long-term solution to the present-day infrastructure, and reduce the dependence on non-renewable sources.

5. Home and Garden Products: Consumer Applications

Furniture and Outdoor Products

Manufacturers create various consumer products using PET flakes. Consumer goods:

-

Outdoor furniture: Weather-resistant patio furniture and garden accessories

-

Storage containers: Durable organizational products for home and commercial use

-

Planters and garden products: UV-resistant containers and landscaping materials

-

Recreational products: Playground equipment and sports goods

6. Electronics and Technology Sector

The electronics industry uses PET flakes in electronics applications for:

-

Device casings: Protective housings for consumer electronics

-

Cable insulation: Electrical insulation materials

-

Component packaging: Anti-static packaging for electronic components

7. Medical and Healthcare Applications

While maintaining strict quality standards, the healthcare sector employs medical-grade PET flakes for:

-

Disposable medical equipment: Non-implantable devices and equipment

-

Protective equipment components: Elements of PPE and safety equipment

-

Medical packaging: Secondary packaging for medical devices and supplies

Quality Standards and Certification in PET Flakes Manufacturing

Quality assurance is not a standard in the PET recycling business; it is a requirement. PET flakes should pass high regulatory and performance requirements to be used in various industries that include textiles, packaging, and automotive. Quality, consistency, environmental compliance, as well as safety, are ensured through adherence to globally recognized certification and strong quality control.

Saheb Fibre is a reliable brand when it comes to eco-friendly production that offers a certified source of high-quality PET flakes and RPSF - Recycled Polyester Staple Fiber. They perform their activities based on global conventions and environmentally friendly operations and supply reliable raw materials to major textile and nonwoven companies. Saheb Fibre is also an aspect of customizing colored RPSF, as it understands the innovations in recycled applications and targets the client's needs.

Industry Certifications

High-quality PET flakes meet various industry certified standards:

-

FDA approval: Food-contact applications require FDA-compliant recycled PET

-

Global Recycled Standard (GRS): Certification for recycled content verification

-

ISO standards: Quality management systems for consistent product quality

-

REACH compliance: European chemical safety regulations

Quality Control Processes

Manufacturers implement rigorous PET flakes quality control measures, including:

-

Contamination testing: Detection and removal of foreign materials

-

Chemical analysis: Ensuring appropriate molecular weight and purity levels

-

Color sorting: Optical sorting for consistent color quality

-

Moisture content control: Proper drying for optimal processing characteristics

Conclusion: PET Flakes Driving Industrial Sustainability

The fact that PET flakes have become common in industries signifies a paradigm shift in the endeavour to achieve sustainable forms of manufacturing. From textiles and packaging to automotive and construction, industries are discovering that recycled PET flakes offer both environmental benefits and economic advantages.

PET flakes price competitiveness makes them a viable option for scaling production sustainably. PET flakes will continue to play a greater part in sustainable manufacturing as technologies continue to develop and as the regulatory requirements prove to be more stringent.m PET bottle flakes price and availability will continue to shape industry decisions.

By accepting such recycled materials, industries today identify themselves as the frontrunners in the circular economy and satisfy their consumers who demand more and more environmentally conscious products.

Innovative materials, such as the PET flakes, are becoming more important in the future of manufacturing, which is why they should be regarded as key elements of the future process of switching towards a more sustainably manufactured industrial world. Every company in every industry must consider using quality recycled PET flakes in the production line as a way of attaining both sustainability objectives and competitive advantage.