When you discard a polyester (PET) bottle, life does not end in the bin; rather, a new cycle of life begins, one that aids in safeguarding the environment and powers various sustainable industries. Rather than ending up in landfills or oceans, these PET bottles are recovered and upcycled into Recycled Polyester Staple Fiber (RPSF), a valuable raw material used in the textile, furnishing, automotive, and construction industries.

This transformation is part of a sophisticated recycling system that converts recycled plastic bottles into a consumable, environmentally friendly product. These PET plastic containers are sorted, washed, shredded into flakes, reviewed for quality, and finally converted into small polyester fibers. These fibers are cut to size and packed into RPSF bales. Both white and colored RPSF are manufactured, depending on the original color of the clear plastic bottles or polyethylene bottles used.

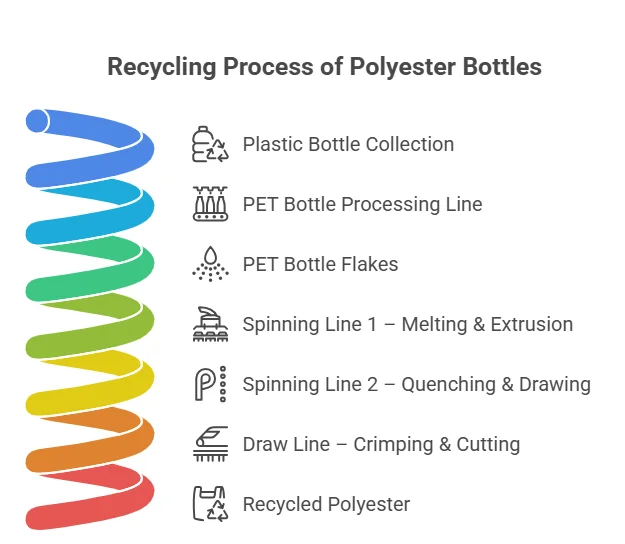

When You Throw Away Polyester Bottles, What Happens To Them?

Step 1: Plastic Bottle Collection

Step 2: PET Bottle Processing Line

Step 3: PET Bottle Flakes

Step 4: Spinning Line 1 – Melting & Extrusion

Step 5: Spinning Line 2 – Quenching & Drawing

Step 6: Draw Line – Crimping & Cutting

Step 7: Recycled Polyester Staple Fibre (RPSF)

Step 1: Plastic Bottle Collection

Used recycled PET bottles are collected from municipal, industrial, and consumer waste streams. These PET bottles serve as the primary raw material in producing RPSF, which directly reduces plastic waste and alleviates the burden on landfills.

Step 2: PET Bottle Processing Line

The bottles that have been collected are sorted, washed, and thoroughly cleaned to eliminate labels and caps from the cleaned bottles and contaminants. The reason why this stage is needed is that only clean and high-quality PET is brought into the recycling line and this is imperative in the production of high-quality grade recycled polyester staple fiber( RPSF).

Step 3: PET Bottle Flakes

The bottles are then shredded into small, even flakes. The resulting flakes are then repeated to be processed by hot and cold wash to remove any other remaining impurities like glue, ink and food in order to harvest clean recycled PET flakes that can then be converted into fibers.

Step 4: Spinning Line 1 – Melting & Extrusion

During the first spinning process, heats of the PET flakes are melted at high temperatures in order to extrude using the spinnerets into continuous polyester filament. It is at this stage of softening of the solid flakes into melted polymer that an extremely important transition is made in the recycling process.

Step 5: Spinning Line 2 – Quenching & Drawing

The extruded filaments are cooled down (quenched) to solidify very quickly, and then tensile stressed (drawn) to orient the polymer chains to increase the strength and flexibility of the fibers in tension. The step is important in realizing the mechanical qualities needed in the end RPSF products.

Step 6: Draw Line – Crimping & Cutting

The crimping of the continuously drawn filaments is carried out to add bulk and texture to the filaments. The crimped filaments are afterward cut into desired lengths (typically 32 mm, 38 mm, or, on the basis of the customer's needs) and can be fitted for various purposes.

Step 7: Recycled Polyester Staple Fibre (RPSF)

The final product is RPSF, which can be produced in both white and colored variants.

-

White RPSF is made from clear PET bottles.

-

Colored RPSF is produced by using color-dyed processes or colored PET bottles. This fiber is packed and ready for use across industries.

Colored RPSF: Sustainable & Customizable

In contrast with regular white ones, colored RPSF is made by directly adding masterbatch dyes to the fiber manufacturing process. This removes the need to go through post-dyeing although it is a greener alternative. It enables the manufacturer to get consistent and bright colors at the fiber level, which leads to an efficient production chain with minimized use of water and chemicals.

Applications of RPSF

1. Textile Industry

RPSF is used to spin yarns for making clothing, carpets, upholstery, and technical textiles and recycled polyester fabric products. It offers durability and comfort while promoting sustainability.

2. Automotive Industry

Used in seat fillings, insulation pads, car trunk liners, and roof linings, providing comfort, acoustic insulation, and environmental benefits.

3. Home Furnishings

Found in cushions, quilts, mattresses, and pillows. RPSF’s soft, fluffy nature makes it an excellent alternative to virgin polyester fill.

4. Geotextiles & Construction

Ideal for reinforcing soil, controlling erosion, and creating filter fabrics for civil engineering projects.

5. Nonwoven Products

Used in filtration materials, medical masks, packaging layers, and insulation padding, thanks to its uniform texture and cost-efficiency.

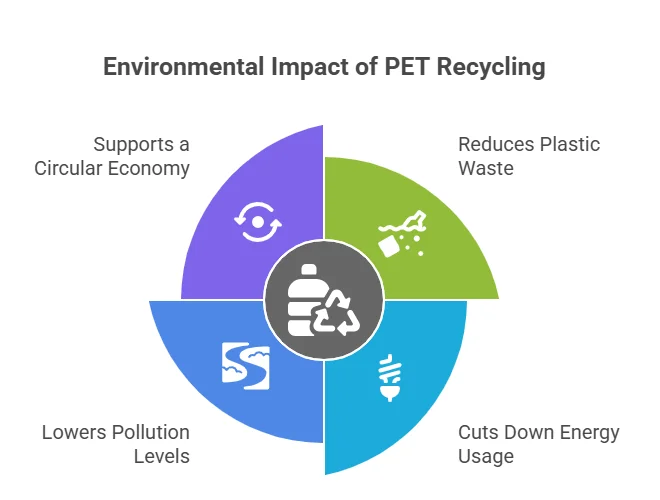

The Environmental Benefits of Recycling PET Bottles

Turning PET bottles into RPSF is not just a technological achievement; it’s a massive win for the environment. Here are the key benefits:

1. Reduces Plastic Waste

PET bottles can be recycled instead of being put to waste, which further reduces the amount of plastics in the landfill or as litter. PET bottles, which normally would have taken hundreds of years to decay, are assigned a sustainable second life.

2. Cuts Down Energy Usage

The process of RPSF manufacturing uses considerably fewer amounts of energy compared with petroleum-based virgin polyester production. This helps in reducing the emission of greenhouse gases and saving valuable fossil energy.

3. Lowers Pollution Levels

PET recycling prevents plastic pollution in rivers, oceans and even forests. They also keep dangerous chemicals out of grounds and underground waters.

4. Supports a Circular Economy

A major case of the circular economy being implemented is indicated in RPSF production- the resources that were used remain in use, a fact that minimizes the use of new materials, and consequently, overall waste. Recycled PET bottles are a perfect example of circular use.

Where to Get High-Quality RPSF?

To achieve a good and long-lasting RPSF, Saheb Fibre is a dependable manufacturer and supplier. Being eco-concerned in manufacturing and innovative in recycling, Saheb Fibre manufactures both white and colored RPSF to suit the industry specifications. Whether you're in textiles, automotive, or industrial manufacturing, Saheb Fibre offers consistent quality, custom specifications, and environmentally responsible solutions using PET bottles.

Conclusion

In conclusion, the journey of a discarded PET bottle doesn’t end in waste; it begins a powerful transformation into Recycled Polyester Staple Fiber (RPSF), contributing to a circular economy and reducing environmental impact. By carefully following a process of recycling, namely sorting, cleaning, melting, and fiberizing, PET waste is transformed into an eco-friendly raw material that can be used in many products. RPSF contributes to green technologies in industries, including textiles, the automotive, building as well and furnishing sectors. With the help of reputable manufacturers, such as Saheb Fibre, any company can enjoy the unlimited supplies of white and colored RPSF, not to mention the contribution to developing a clean and green future.