The modern construction industry is undergoing a significant transformation. As cities grow denser and energy demands increase, architects and engineers are now prioritizing comfort, efficiency, and sustainability in every structure they design. Whether it’s a residential apartment, commercial building, or industrial unit, the need for effective insulation is stronger than ever.

In this shift, Recycled Polyester Staple Fiber (RPSF) has emerged as a reliable and eco-friendly insulation material. Known for its superior sound and thermal control properties, RPSF is gaining traction among builders, manufacturers, and sustainability-conscious brands. By converting plastic waste into high-performance fiber, RPSF also aligns with global environmental goals, making it one of the most promising insulation materials of the future.

What is RPSF?

RPSF, or Recycled Polyester Staple Fiber, is produced by transforming recycled PET bottles, post-consumer plastics, and discarded pet plastic material into soft, durable fibers. These materials undergo cleaning, sorting, shredding, and melting before being spun into fine polyester strands.

This process not only reduces the burden on landfills but also replaces the need for virgin polyester production, which requires high energy and fossil-fuel consumption. The result is a polyester sustainable fiber that offers outstanding performance while contributing to a greener planet.

By choosing RPSF, manufacturers and construction companies support the circular economy and promote the responsible use of recycled plastic bottles. Companies like Saheb Fibres Pvt. Ltd. have been instrumental in producing high-quality RPSF that meets global insulation standards.

The Science Behind RPSF and Its Insulation Capabilities

The exceptional insulation capabilities of RPSF stem from its fiber structure. Each strand contains thousands of micro-gaps that trap air effectively. This trapped air acts as a natural barrier preventing noise transmission and reducing heat transfer.

Why the fiber design matters:

-

Dense network = High sound absorption

-

Air pockets = Strong thermal resistance

-

Soft flexibility = Better vibration control

-

Hydrophobic nature = Moisture resistance

These characteristics make RPSF a robust choice for both acoustic and thermal insulation, outperforming many traditional insulation materials in safety, longevity, and eco friendliness.

Importance of Acoustic & Thermal Insulation in Modern Buildings

In today’s fast-moving urban world, buildings are exposed to challenges that didn't exist decades ago. Traffic noise, machinery sounds, dense neighborhoods, and fluctuating climates make indoor comfort a difficult goal.

For acoustic comfort:

-

Noise from roads, offices, and public areas affects health and productivity

-

Soundproofing has become a necessity in homes, studios, schools, and hospitals

For thermal comfort:

-

Energy consumption is continuously rising

-

Maintaining stable indoor temperatures reduces electricity costs

-

Insulated buildings experience better cooling and heating efficiency

RPSF meets both needs making it an insulation solution that aligns with the performance demands of modern architecture.

How RPSF Helps in Acoustic Insulation

RPSF has a soft, dense fiber structure that absorbs sound instead of reflecting it. This makes rooms quieter and reduces echo or vibration.

Benefits of RPSF for sound insulation:

-

Absorbs mid-frequency and high-frequency noise

-

Reduces echo and reverberation

-

Performs well even in humid conditions

-

Does not irritate the skin like fiberglass

-

Easy to cut, install, and shape

Common applications:

-

Home theaters and living rooms

-

Recording studios

-

Corporate offices and conference rooms

-

Auditoriums and classrooms

-

Industrial noise-reduction panels

Because it maintains its shape for years, RPSF offers long-term acoustic performance without frequent replacement.

How RPSF Works for Thermal Insulation

RPSF insulates buildings by trapping air inside its fibers. These air pockets act as a natural barrier, preventing heat from entering or escaping a room.

Thermal advantages include:

-

Keeps interiors cooler in summer and warmer in winter

-

Reduces electricity consumption

-

Helps HVAC systems run more efficiently

-

Provides stable performance over time

-

Does not support microbial growth

Where it is used:

-

Residential walls and ceilings

-

Commercial building insulation

-

HVAC duct insulation

-

Prefabricated structures

-

Industrial machinery insulation

RPSF is especially useful in regions with extreme temperatures, where energy savings are essential.

Environmental Advantages of Choosing RPSF

One of the strongest reasons behind RPSF’s growing popularity is its positive environmental impact.

Sustainability benefits:

-

Made from recycled pet bottles

-

Significantly reduces landfill waste

-

Requires less manufacturing energy compared to virgin polyester

-

Non-toxic and safe for indoor environments

-

Fully recyclable, supporting circular economy practices

Its sustainable production process and low carbon footprint make RPSF a preferred choice for industries looking to shift from traditional insulation to truly environmentally friendly insulation solutions.

By choosing RPSF, industries support cleaner production methods and reduce plastic pollution. Manufacturers like Saheb Fibres Pvt. Ltd. are contributing significantly to this sustainability shift by producing high-quality recycled polyester fiber.

RPSF vs Traditional Insulation Materials

Here’s how RPSF compares to commonly used insulation materials:

|

Material |

Advantages |

Limitations |

|

RPSF |

Recycled, safe, lightweight, moisture-resistant, durable |

Slightly higher initial investment |

|

Fiberglass |

Good insulation |

Can irritate skin, not eco friendly |

|

Mineral Wool |

Fire resistant |

Heavy and less flexible |

|

PU Foam |

Strong thermal performance |

Not recyclable, chemical-based |

RPSF offers an excellent blend of safety, sustainability, and long-term performance, making it a smarter choice for modern construction needs.

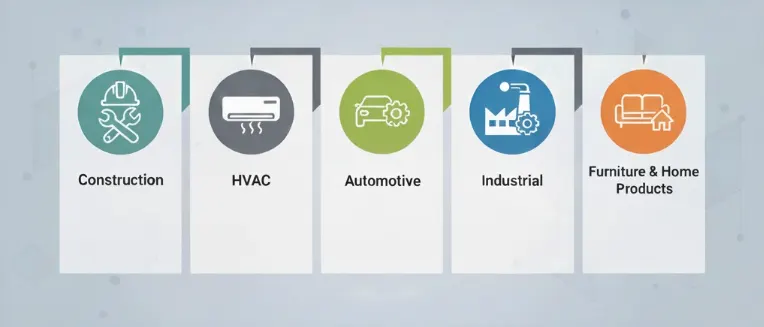

Practical Applications Across Industries

RPSF is one of the most versatile insulating materials available today, widely used across:

1. Construction

-

Wall, ceiling, and panel insulation

-

Acoustic partitions

-

Prefabricated structures

2. HVAC

-

Duct insulation

-

Air filtration systems

3. Automotive

-

Interior soundproofing

-

Engine compartment insulation

4. Industrial

-

Machinery insulation

-

Noise control barriers

5. Furniture & Home Products

-

Mattresses

-

Upholstery padding

-

Soft furnishing components

Its adaptability, durability, and cost-effectiveness make RPSF suitable for nearly every sector.

Why Industries Are Rapidly Adopting RPSF

The global market is clearly shifting toward sustainable and high-performance materials. RPSF ticks all boxes environmental, economic, and functional.

Factors driving rapid adoption:

-

Rising demand for eco friendly materials

-

Availability of recycled polyester fiber

-

Cost-efficient production from recycled poly

-

Customer preference for sustainable living

-

Government support and green-building certifications

-

Improved manufacturing technologies led by brands like Saheb Fibres Pvt. Ltd.

These trends position RPSF as an essential component of future-ready insulation solutions.

Future of Insulation: Why RPSF Will Lead the Market

As environmental regulations become stricter and consumers prioritize health and sustainability, traditional insulation materials are losing relevance. RPSF, with its recycled origins and exceptional performance, is poised to dominate the insulation market.

The future belongs to RPSF because:

-

It supports global climate goals

-

It reduces plastic pollution

-

Innovation in rPET polyester is growing rapidly

-

It integrates perfectly with smart, energy-efficient building designs

With continuous technological advancements, RPSF will only become more efficient, affordable, and widely adopted.

Conclusion

RPSF has proven itself to be a powerful insulation material offering the perfect balance of acoustic comfort, thermal stability, and environmental responsibility. As industries strive to create buildings that are quieter, greener, and more energy-efficient, RPSF stands out as a future-proof solution.

By transforming recycled plastic bottles into high-performance insulation fibers, RPSF delivers exceptional value across applications. Companies like Saheb Fibres Pvt. Ltd. are leading this movement by providing sustainable, high-quality RPSF that supports modern construction needs and environmental goals.

In a world aiming for sustainability and comfort, RPSF is not just an alternative it is the ideal choice for a smarter, greener, and more efficient future.

FAQ Section

1. Is RPSF safe for residential use?

Yes, it’s non-toxic, non-irritating, and safe for all building types.

2. Can RPSF insulation be used in all types of buildings?

Absolutely , it’s suitable for residential, commercial, industrial, and infrastructure projects.

3. How does RPSF help in reducing energy costs?

By reducing heat transfer and maintaining indoor temperature, RPSF lowers HVAC energy consumption.

4. Is recycled polyester fiber safe and non-toxic?

Yes. It’s made from recycled poly and rPET polyester, free from harmful chemicals.

5. How does RPSF compare to glass wool or foam insulation?

It offers superior acoustic absorption, equal or better thermal performance, and is eco friendly and recyclable.