Introduction

Imagine this: a procurement manager orders PET flakes for textile production. But when the shipment arrives, the flakes don’t melt correctly, the color output fails, and production grinds to a halt. The culprit? Incorrect PET flake grade selection.

In industries where precision and consistency matter, this kind of mistake costs more than money it damages timelines, reputation, and client trust. The issue often stems from one simple gap: not understanding PET flake grades and their exact match to end-use requirements.

That’s where Saheb Fibres Pvt. Ltd., a leading name in PET flake manufacturing and recycling, bridges the gap. By helping buyers understand flake quality, contamination levels, and application compatibility, they ensure every ton of material performs exactly as expected.

This guide breaks down everything you need to know from PET flake grades and quality parameters to application matching, pricing, and market trends helping procurement professionals make informed, cost-efficient decisions.

What Are PET Flakes?

PET flakes are small, clean pieces of recycled PET plastic primarily derived from used polyethylene bottles and recycled PET bottles.They serve as the foundational raw material for countless applications across packaging, textiles, construction, and automotive industries.

Each flake is lightweight, semi-transparent, and has a crisp texture that distinguishes it from pellets or chips. These flakes are often categorized by size, clarity, and color consistency.

From Bottle to Flake: The Journey

-

Collection: Gathering post-consumer PET bottles and polyethylene bottles.

-

Sorting: Separation by color and polymer type.

-

Label & Cap Removal: Eliminating PVC and polypropylene contamination.

-

Washing: Processed as hot-wash PET flakes for premium purity or cold-wash for lower-grade use.

-

Shredding: Bottles are cut into uniform flakes.

-

Inspection: Final visual and mechanical screening ensures purity and color uniformity.

This process transforms everyday PET plastic waste into a valuable industrial resource ready for reuse in advanced manufacturing.

Why PET Flake Quality Matters

Not all pet plastic flakes are created equal, and here's why that matters: contamination directly impacts your end product's quality, appearance, and performance.

A soft toy manufacturer needs pristine, low-contamination flakes that spin into soft, hypoallergenic fibers safe for children. Meanwhile, a geotextile manufacturer for road construction can work with higher contamination levels since the material goes underground where appearance doesn't matter.

Using the wrong grade creates several problems:

-

Processing inefficiency: Contaminants clog extruders, requiring frequent shutdowns

-

Quality failures: Discoloration, weak spots, or odor issues in final products

-

Equipment damage: Metal particles can damage expensive machinery

-

Cost overruns: Rejected batches, rework, and wasted materials

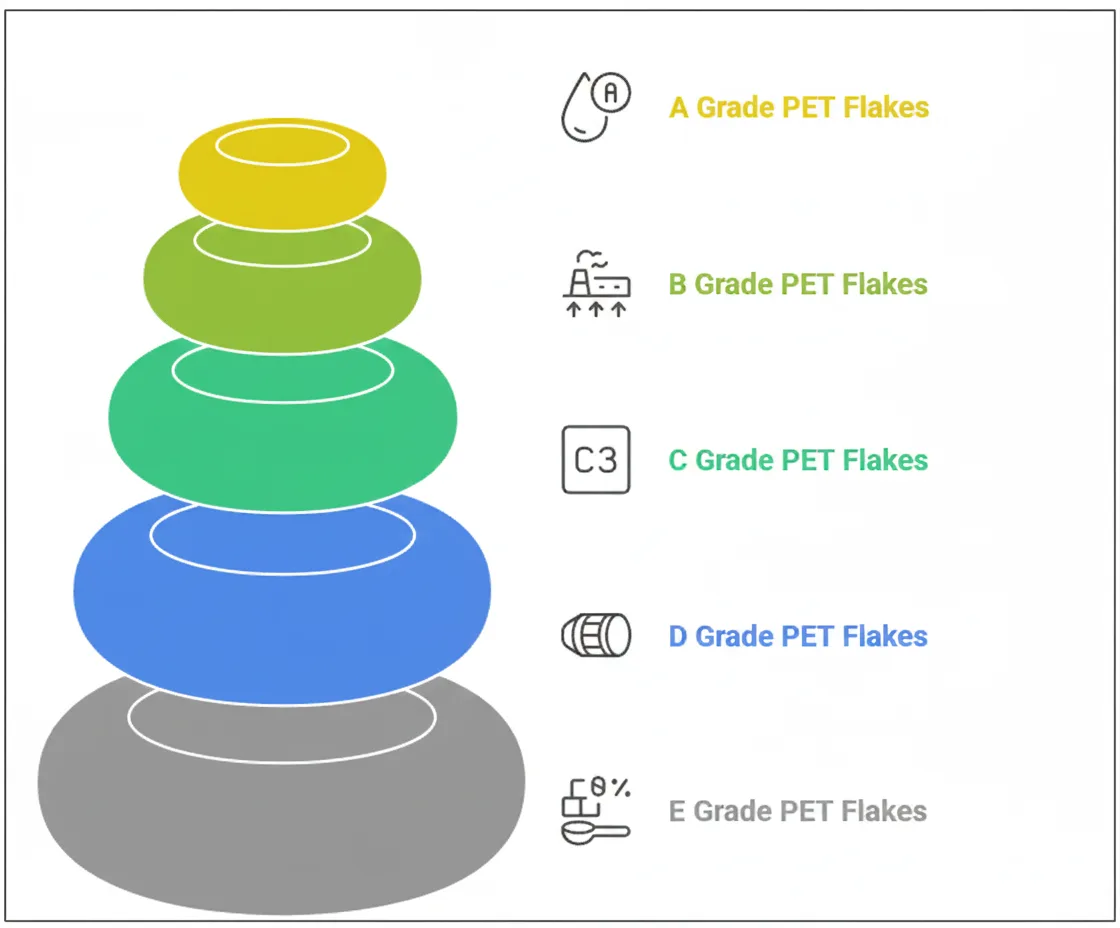

PET Flake Grading: The Five-Grade System

How Grades Are Determined

The industry uses a standardized A-to-E classification system, with color-coded tags for easy identification. Each grade is defined by specific contamination thresholds measured in parts per million (ppm).

Key Quality Parameters

Contamination Levels:

-

PVC Content: The most critical parameter. PVC melts at different temperatures than PET, causing processing issues and product defects. Even small amounts create problems in high-quality applications.

-

Wrapper & Label Residue: Paper and plastic fragments from incompletely removed labels. Affects appearance and can cause blockages.

-

Metal Content: Traces from bottle caps, aluminum seals, or sorting equipment. Major equipment hazard.

-

PP (Polypropylene): From caps and closures. Different melting properties than PET.

-

Organic/Dirty Material: Food residue, unwashed particles that create odor and contamination.

Processing Parameters:

-

pH Value: Chemical balance affecting fiber production, dyeing efficiency, and material stability. Industry standard maintains pH around 7.0.

-

Moisture Content: Excess moisture causes processing problems and material degradation. Proper drying keeps it below 0.70%.

-

Glue Content: Adhesive residue from label removal. Particularly problematic in high-quality textile applications.

-

Total PPM: Cumulative contamination indicator the lower, the better.

-

Color Consistency: Critical for applications requiring dyeing or color matching.

The Five Grade Classifications

|

Grade |

Quality Level |

Contamination (Total ppm) |

Typical Use Cases |

Price Range |

|

A Grade (Premium) |

Exceptional purity |

≤ 100 ppm |

Food packaging, high-end textiles, medical uses |

Highest |

|

B Grade (High Quality) |

Low contamination |

≤ 150 ppm |

Apparel textiles, bottle-to-bottle recycling, quality packaging |

Mid-High |

|

C Grade (Standard) |

Moderate |

≤ 350 ppm |

General textiles, straps, industrial packaging |

Mid-Range |

|

D Grade (Economy) |

Acceptable for bulk uses |

≤ 480 ppm |

Construction, non-critical applications |

Budget |

|

E Grade (Industrial) |

Highest contamination |

> 480 ppm |

Fillers, non-woven liners |

Lowest |

Matching PET Flake Grades to Your Application

Choosing the right grade is crucial. Here's your comprehensive application guide:

1. A Grade PET Flakes – Premium & High Purity (≤100 ppm)

A Grade PET flakes are the cleanest, brightest, and most consistent in the industry. They undergo the most advanced hot-washing and optical sorting to achieve near-zero contamination. This grade is chosen when melt purity, color consistency, and mechanical strength cannot be compromised.

Best For:

-

Food packaging

-

High-end textile fiber

-

Bottle-to-bottle recycling

-

Baby products

-

Clear packaging sheets

Buyer Tip: Choose A Grade when your product undergoes dyeing, heating, or extrusion even minor impurities cause defects.

2. B Grade PET Flakes – High Quality Industrial (≤150 ppm)

B Grade offers excellent clarity and low contamination but is priced more competitively than A Grade. It is widely used across textile and packaging industries where visual appearance still matters.

Best For:

-

Apparel textiles

-

Non-food packaging

-

Strapping & ropes

-

Commercial carpets

Buyer Tip: Ideal when you need durability and clean melt flow, but not food-grade standards.

3. C Grade PET Flakes – Standard Production Grade (≤350 ppm)

C Grade is the most versatile and cost-efficient grade for industries focused on strength and volume rather than aesthetics.

Best For:

-

Automotive interiors

-

Geotextiles

-

Industrial packaging

-

Molded parts

Buyer Tip: Suitable for products where color variation or minor contamination is acceptable.

4. D Grade PET Flakes – Economy for Industrial Use (≤480 ppm)

D Grade flakes tolerate moderate contamination levels and are best suited for heavy-duty or hidden applications.

Best For:

-

Construction materials

-

Non-woven liners

-

Road underlayment

-

Agriculture nets

Buyer Tip: Great for products that do NOT require dyeing, fiber spinning, or color consistency.

5. E Grade PET Flakes – Non-Critical & Filler Applications (>480 ppm)

E Grade is the most economical option. These flakes are often used where melt quality, appearance, or tensile strength are not top priorities.

Best For:

-

Filling materials (pillows, cushions, toys)

-

Heavy-duty liners

-

Industrial fillers

Buyer Tip: Not suitable for spinning, extrusion, or injection molding applications.

Quick Summary: PET Flake Grades at a Glance

|

Grade |

Purity Level |

Contamination (ppm) |

Best For |

|

A Grade |

Premium |

≤ 100 |

Food packaging, high-end textiles, bottle recycling |

|

B Grade |

High Quality |

≤ 150 |

Apparel, ropes, non-food packaging |

|

C Grade |

Standard |

≤ 350 |

Geotextiles, automotive, industrial packaging |

|

D Grade |

Economy |

≤ 480 |

Construction, shade nets, liners |

|

E Grade |

Industrial |

> 480 |

Cushions, fillers, non-critical use |

PET Flakes Price Dynamics

1. Grade-Based Pricing

-

A Grade: 20–30 % higher than C Grade

-

B Grade: 10–15 % higher than C Grade

-

D & E Grades: Lower cost but limited applications

2. Market Factors

-

Virgin PET prices: When crude oil costs rise, recycled flakes become more competitive.

-

Supply & demand: Packaging and textile peak seasons influence price swings.

-

Location: Transportation and logistics add regional variations.

-

Processing method: Hot-wash PET flakes cost 5–10 % more due to cleaner output.

3. Volume & Contract Terms

-

Bulk orders (20 tons +) = 5–15 % discount.

-

Long-term contracts = price stability.

-

Spot purchases = premium pricing.

4. Certification Premium

-

GRS-certified: + 8–12 %.

-

Food-grade: + 15–25 %.

-

Standard industrial: Base rate.

5. Evaluating True Value

Instead of focusing only on PET flakes price, factor in contamination, process yield, and supplier reliability. A slightly higher-grade rPET flake often delivers lower total cost per finished product.

Quality Assurance: What Sets Premium Suppliers Apart

Not all pet flake suppliers maintain consistent standards. Here's what sets premium manufacturers apart:

Advanced Processing: Multi-stage washing systems producing consistent hot wash pet flakes with verified purity levels. Every batch meets specified grade parameters.

Rigorous Testing: Laboratory analysis at every production stage PVC content, metal detection, moisture testing, pH verification. Quality reports accompany every shipment.

Transparent Grading: Color-coded tagging system makes grade identification foolproof. No confusion about what quality you're receiving.

Certifications That Matter: ISO 9001 quality management and Global Recycled Standard (GRS) certification ensure international compliance. Food-grade certifications where applicable.

Reliable Supply: Consistent production capacity means your orders ship on schedule. No surprise shortages disrupting your manufacturing.

Technical Support: Expert guidance helps you select the optimal grade for your specific application, avoiding costly mistakes.

The Future of the PET Flakes Market

The pet flakes recycling industry is evolving rapidly, creating new opportunities for informed buyers.

Industry Trends Shaping Demand:

-

Expanding applications: Innovation bringing rpet flake into construction, automotive composites, and technical textiles

-

Technology improvements: Advanced sorting and AI-powered quality control producing more consistent grades

-

Regulatory momentum: Government mandates requiring minimum recycled content in products

-

Circular economy growth: Bottle-to-bottle recycling technologies making food-grade material more accessible

-

Price competitiveness: Rising virgin PET costs make recycled alternatives increasingly attractive

What This Means for Buyers:

-

More reliable quality across all grades

-

Better price stability reducing procurement risk

-

Increased supplier competition improving service

-

Enhanced traceability meeting corporate sustainability goals

-

Specialized grades for niche applications

Conclusion

Choosing the right pet flake grade isn't about finding the cheapest option it's about matching quality to application for optimal performance and value. Whether you're manufacturing outdoor gear, commercial carpets, automotive interiors, or construction materials, understanding grade specifications prevents costly mistakes and ensures production success.

Saheb Fibres Pvt. Ltd. stands ready as your trusted partner in this journey, offering transparent grading, consistent quality, and expert guidance to help you select the perfect grade for your needs. With proper grade selection, you'll reduce costs, improve product quality, and contribute meaningfully to the circular economy through pet flakes recycling.

Ready to make informed purchasing decisions? Understanding grades isn't just knowledge it's your competitive advantage in manufacturing excellence.

FAQ: Common Buyer Questions

1. What are PET flakes used for?

They’re the base raw material for textiles, packaging, geotextiles, and molded consumer goods.

2. How is PET flake quality tested?

Suppliers evaluate PVC ppm, moisture levels, and impurity content through spectroscopy and filtration analysis.

3. What’s the difference between hot-wash and cold-wash PET flakes?

Hot-wash removes oil, glue, and label residues for cleaner, high-grade flakes; cold-wash is suitable for non-critical applications.

4. What factors affect PET flakes price?

Grade, purity, washing process, certification, logistics, and overall market supply-demand dynamics.

5. Can PET flakes be recycled again?

Yes. High-quality recycled polyester fabric and recycled polyester fiber produced from flakes can re-enter the recycling stream, extending the circular lifecycle.