The tendency towards sustainability in the textile industry has put recycled polyester staple fiber (RPSF) under the spotlight as one marker that can be used to change the game of the regenerated polyester. Denier is one important specification that determines the quality and application of RPSF because this measurement is important in influencing the quality and performance characteristics of the fabric such as the feel and the application it is used for. It is critical to understand the term denier in light of recycled polyester in a bid to influence the efforts of manufacturers, designers and those concerned with sustainability to make informed decisions about the eco-friendly textile option.

Understanding Denier: The Foundation of Fiber Classification

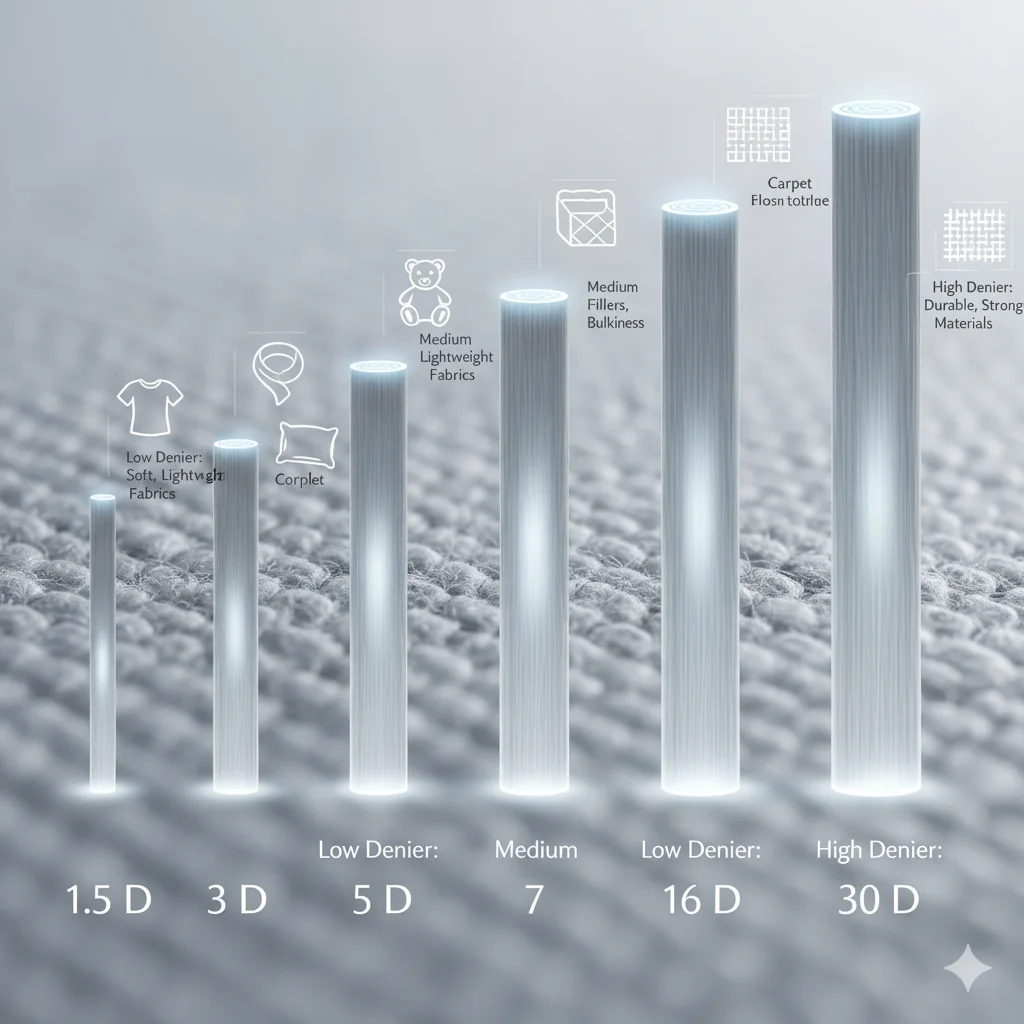

Denier is the measure of the weight in grams of 9,000 meters of a steady fiber or yarn. This system of measurements has been used on silk filaments, but is now the global standard of measuring synthetic fibers, including the recycled polyester fiber. In practice, deniers measure the thickness or thickness of individual fibers, lower denier (thinner, lighter) fibers, and higher deniers (thicker, heavier) fibers.

In the case of recycled polyester staple fiber, its denier can vary anywhere between 0.9 and 15 with each denier meeting a different application in the textile industry. The exact hand on denier throughout the production process enables manufacturers to produce recycled poly fabric that has the specifications needed in different applications including delicate clothing and rugged manufacturing environments.

What is Recycled Polyester Staple Fiber (RPSF)?

Recycled polyester staple fiber is a groundbreaking style of textile manufacturing that converts waste into quality fibers. This starts with the collection of PET bottles, other recycled plastic bottles that are in the post-consumer waste streams. These PET plastic containers are carefully cleaned, sorted, and processed into RPET polyester, an eco-friendly alternative that retains the same exalted performance features as virgin polyester with a far reduced environmental footprint.

From recycling PET bottles to recycled polyester clothing, creating new clothes means that highly advanced production technologies are used to turn plastic waste into polymer chips that are melted and extruded through spinnerets in order to produce filaments. Staple fibers are then cut into pre-determined lengths such that all points of deniers are meticulously taken care of.

The Role of Denier in RPSF Quality and Performance

1. Fabric Hand and Drape

Lower denier RPSF (0.9-3.0 denier) yields a higher feel quality and drape, and is suited to recycled polyester clothing products like intimate apparel and active and fashion clothes. The more subtle fibers allow a smooth surface of the fabric and better comfort along the skin.

The denier is higher at the 6.0-15 denier range, which makes the fabric more structured and durable, a wise property of home textile, automotive and technical applications where strength and resilience are the main considerations rather than softness of the materials.

2. Yarn Strength and Uniformity

The denier specification affects how recycled poly fabric performs during spinning and weaving processes. Medium denier ranges (3.0-6.0) often provide optimal balance between processability and final fabric properties, ensuring consistent yarn formation while maintaining adequate strength for most textile applications.

3. Thermal Properties and Insulation

Denier specification has an influence on the recycled poly fabric performance in spinning and weaving processes. Such medium deniers (3.0-6.0) tend to achieve an economical balance between processability and end product specification, where adequate yarn formation resiliency is achieved with sufficient strength to suit most finished products.

Recycled polyester fabric of different denier simplifications affects thermal insulation. Fibers at higher deniers form more air spaces in fabric structures to increase thermal insulation properties in winter wear and technical textiles.

Manufacturing Excellence in RPSF Production

Manufacturing high-volume, efficient recycled polyester staple fiber with all specific denier requirements is something that demands advanced production and quality control regimens. The steps start with meticulous processing and selection of recycled plastic bottles to avoid contaminants and process it to ensure homogenous raw materials to make fibers with consistent properties.

The calibrated parameters during the melt spinning stage are the temperature, spinneret, and draw ratios in order to create the desired denier dimensions. Today, RPSF manufacturers incorporate real-time monitoring instruments, which measure the fiber diameter continuously, and adjust lots of other processing parameters to ensure denier consistency within tight tolerances.

Quality assurance practices involve periodic or regular testing of denier of fibers according to an official standard like ASTM D1577 or an international equivalent. This ensures that the recycled poly products are of the specified requirements and they perform in low-stream textile manufacturing processes.

About Saheb Fibre - Premium RPSF Product Range

As a quality manufacturer and supplier of Recycled Polyester Staple Fiber (RPSF), Saheb Fibre is dedicated to sustainable textile solutions that lead to the generation of value out of waste products. Our expertise in utilizing the latest technology in manufacturing RPSF from recycled PET bottles and applying strict quality standards ensures quality RPSF is manufactured with consistent fiber properties over different denier ranges with varying cut lengths. High-tech production operations provide excellent fiber uniformity, maximum dyeability and highly dependable performance features well suited to the rigorous demands of textile manufactures, apparel brands and industrial customers across the globe.

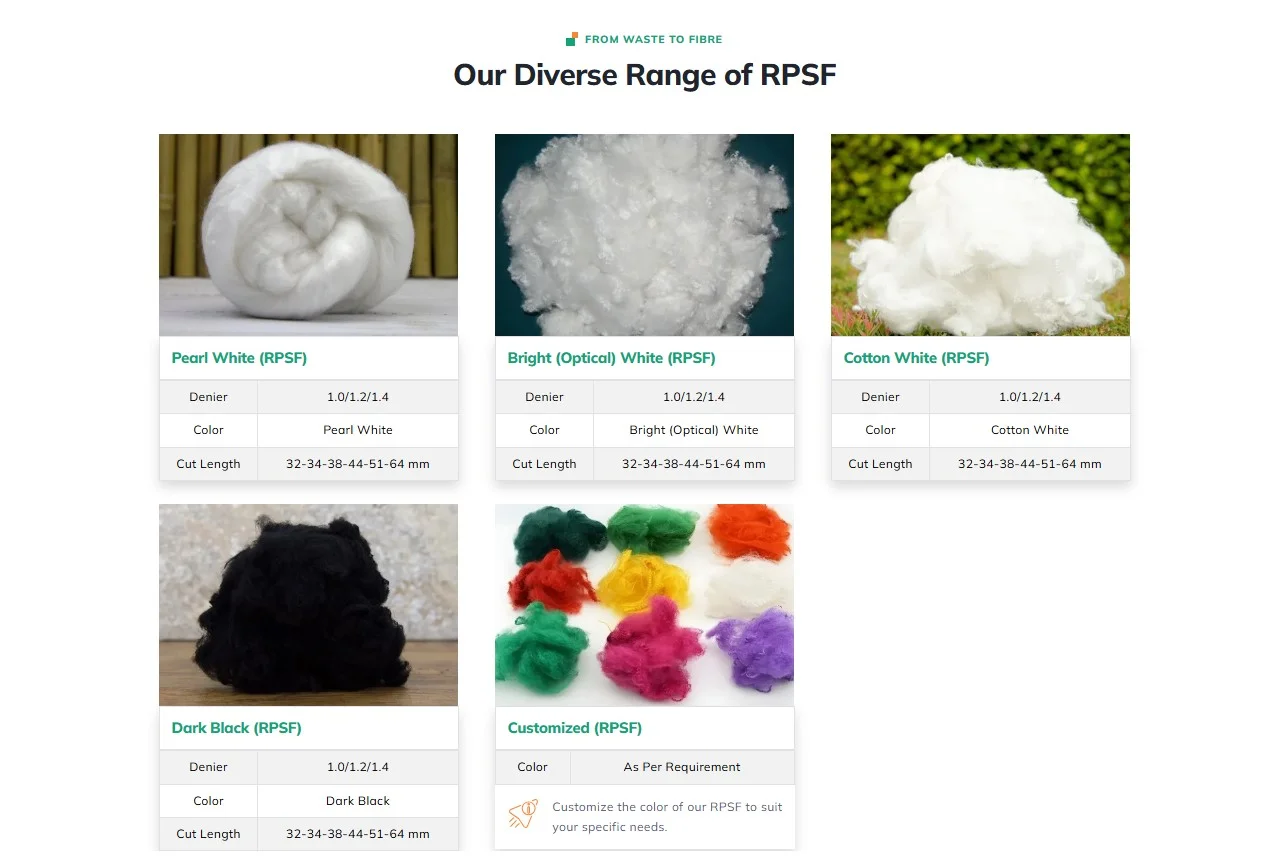

Saheb Fibre’s RPSF Product Portfolio

1. Pearl White RPSF

- Denier Options: 1.0/1.2/1.4

- Color: Pearl White

- Cut Length: 32-34-38-44-51-64 mm

- Applications: Premium apparel, intimate wear, and luxury textiles requiring refined aesthetics and soft hand feel

2. Bright (Optical) White RPSF

- Denier Options: 1.0/1.2/1.4

- Color: Bright (Optical) White

- Cut Length: 32-34-38-44-51-64 mm

- Applications: High-visibility textiles, activewear, and fashion garments demanding brilliant whiteness and color vibrancy

3. Cotton White RPSF

- Denier Options: 1.0/1.2/1.4

- Color: Cotton White

- Cut Length: 32-34-38-44-51-64 mm

- Applications: Natural-look fabrics, home textiles, and blended yarns for an authentic cotton-like appearance

4. Dark Black RPSF

- Denier Options: 1.0/1.2/1.4

- Color: Dark Black

- Cut Length: Multiple options available

- Applications: Fashion apparel, automotive textiles, and technical applications requiring deep, rich black coloration

5. Customized RPSF

- Color: As Per Customer Requirement

- Specifications: Tailored to specific application needs

- Applications: Specialized textile projects, brand-specific color matching, and unique performance requirements

Applications Across Industries

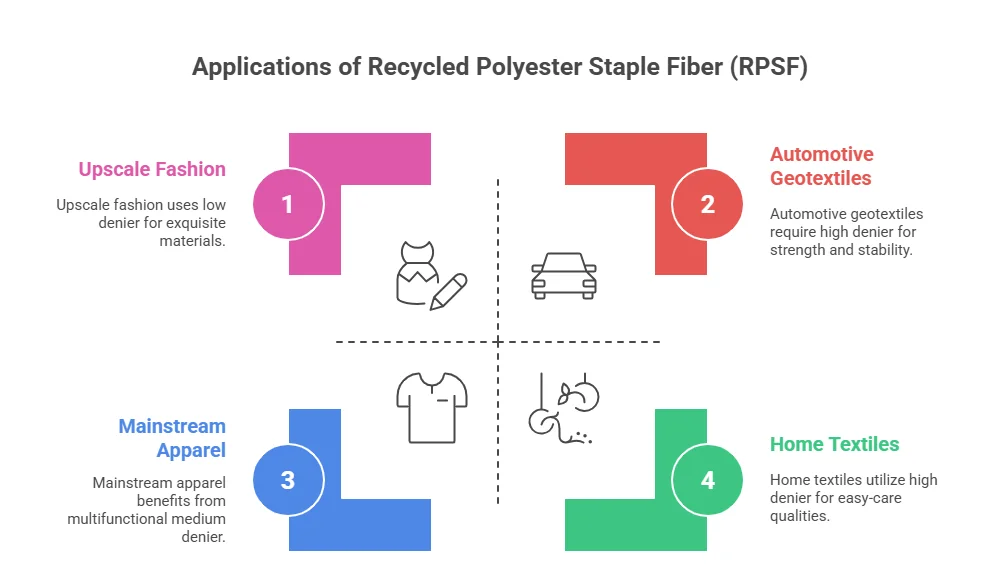

1. Apparel and Fashion

The fashion industry is getting in contact with recycling polyester textiles solutions, and there are several types of deniers available for different types of garments. RPSF with a fineness (1.0-2.0 denier) is suitable to produce exquisite materials used in up-scale fashion, whereas the medium denier (2.5-4.0 denier) range is multifunctional in mainstream apparel applications.

Referring to the recycled polyester clothing made of the correct denier RPSF, it will achieve a similar performance as virgin polyester but then the concept of circular economy can be achieved. Fashion brands also use such sustainable materials in their collections, proving the commercial viability of polyester sustainable solutions.

2. Home Textiles and Furnishings

Recycled plastic fabric made using a higher denier RPSF has wide-ranging home textile applications due to the strength and easy-care qualities of the material. Curtains, upholstery, and bedding products are made with 4.0-8.0 denier specifications to provide comfort-life blends.

3. Technical and Industrial Applications

Niche markets such as automotive, filtration and geotextiles may need more denier RPSF (8.0-15 denier) to achieve performance goals of strength, chemical resistance, and dimensional stability. These products demonstrate the flexibility of RPET polyester further than being used in the textile industry.

Sustainability Impact and Environmental Benefits

The environmental benefits of recycled polyester staple fiber go well beyond that of landfill waste elimination. Compared to the use of virgin polyester, one ton of RPSF manufactured using PET bottles entails the avoidance of 2,000 plastic bottles in waste streams and an energy reduction used as high as 50 percent.

The specification of the denier has a vital role in maximizing these environmental benefits. Due to optimized denier selection, recycled poly fabric effectively delivers its results on the target application, increasing product lifespan and eliminating the necessity of frequent replacements.

Carbon footprint shallowing is one of the key benefits, with recycled plastic fabric generally producing 75% less CO2 emission during manufacturing compared with virgin plastic fabrics. Such environmental performance would also be a good choice to brands that would like to pursue sustainability goals.

Quality Considerations and Selection Criteria

Choosing a suitable denier specification for recycled polyester fiber applications is an issue which needs attention to the end-use and processing capabilities, and expected performance. Even such parameters as tensile strength, elongation performance, and thermal properties are tied to denier specifications and have to be considered alongside given application requirements.

A testing protocol is supposed to ensure that RPSF is set to relevant industry standards along with ensuring that recycled content percentages are in line with sustainability goals. Cooperation between fiber makers, textile manufacturers, and their end-users helps to optimize fiber denier selection to a specific application.

Future Trends and Innovation

Development of polyester recycled staple fiber technology has been progressing further to new heights in terms of quality and the scope of application. Advances in denier control, fiber modification of processes, and developments in blending technologies have the potential to further improve the performance and versatility of any sustainable textile solution.

New uses in smart and medical textiles, advanced composites, etc., are likely to add strength to the rising demand for specialized denier specifications, enhancing the use of recycled poly materials in high-performance product operations.

Conclusion

The denier of recycled polyester staple fiber is a crucial understanding that makes the difference between an educated and an uneducated choice towards the type of choices to make about environmentally friendly textiles. Exact specification of RPSF denier ranges and use in corresponding ranges is highly important as the industry puts more emphasis on the principles of the circular economy to achieve both performance and sustainability goals.

Recycled plastic bottles are transformed into fabric in high-quality recycled polyester fabric through the control of the denier specification, a clear indicator of how waste can become an important resource in sustainable manufacturing. By choosing proper denier classes based on particular uses, manufacturing companies can achieve the best product performance and environmental friendliness by reducing the impact on the environment, which is becoming a more environmentally friendly textile industry.